Uhlolojikelele

I-304 insimbi engagqwali iwuhlobo lwensimbi engagqwali yendawo yonke, ukumelana nokugqwala kunamandla kunochungechunge lwama-200 ensimbi engagqwali, ukumelana nokushisa okuphezulu nakho kungcono, kungaba kufika ku-1000-1200 degrees.304 insimbi engagqwali inokumelana nokugqwala okuhle kakhulu kanye nokumelana nokugqwala phakathi kwezinhlamvu. Insimbi engagqwali engu-304 inokumelana nokugqwala okuqinile.Iphinde ibe nokumelana nokugqwala okuhle kwesisombululo se-alkali kanye nama-acid amaningi e-organic kanye ne-inorganic.

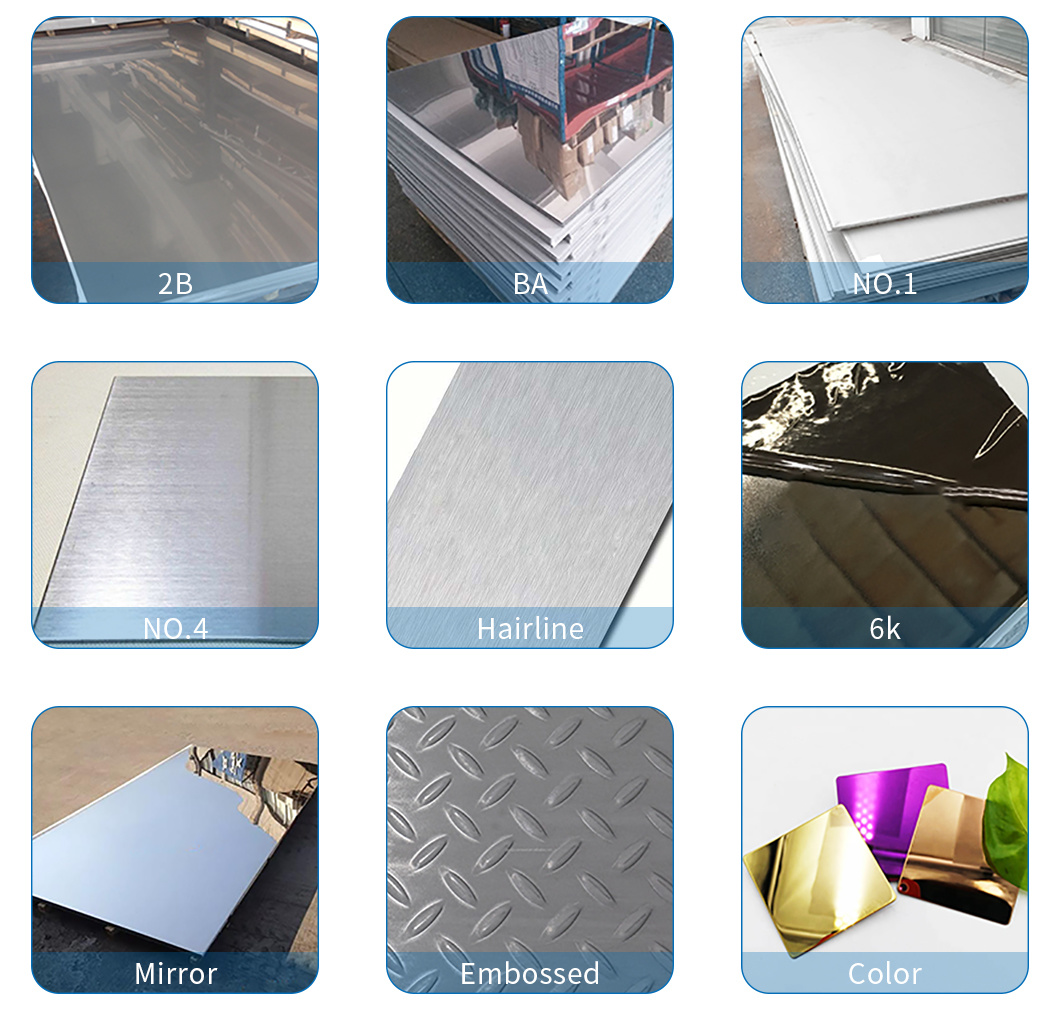

Ukucaciswa

| I-Surface Qeda | Incazelo |

| 2B | Ukuqedwa okukhanyayo, ngemva kokugoqa okubandayo, ngokwelashwa kokushisa, kungasetshenziswa ngokuqondile, noma njengesinyathelo sokuqala sokupholisha. |

| 2D | Indawo ebuthuntu, ebangelwa ukugoqeka okubandayo kulandela ukuhoxiswa nokwehliswa. Ingase ithole ukudlula kokukhanya kokugcina kumaroli angapholishiwe. |

| BA | I-Annealed finish ekhanyayo etholakala ngokuhlanganisa izinto ngaphansi komkhathi ukuze isikali singakhiqizi phezulu. |

| No.1 | Isiphetho esimahhadlahhadla, esibuthuntu, esiphumela ekugiqekeni okushisayo kuya kugqinsi olucacisiwe. Kulandelwa ukuhunyushwa nokwehliswa. |

| No.3 | Lokhu kuqedwa kupholishwa ngo-No.100 kuya ku-No.120 abrasive ecaciswe ku-JIS R6001. |

| No.4 | Lokhu kuqedwa kupholishwa ngo-No.150 kuya ku-No.180 abrasive ecaciswe ku-JIS R6001. |

| Izinwele | Isiphetho esihle, esivikelwe ifilimu ye-PVC ngaphambi kokusetshenziswa, esetshenziswa ku-kitchenware, |

| Isibuko esingu-8K | I-"8" ku-8K ibhekisela engxenyeni yezingxenye ze-alloy (insimbi engagqwali engu-304 ngokuyinhloko ibhekisela kokuqukethwe yizakhi), "K" ibhekisela ebangeni lokubonakala ngemva kokupholishwa. I-8K mirror surface iyibanga elingaphezulu kwesibuko eliboniswa insimbi ye-chrome nickel alloy. |

| Igcizelelwe | Amashidi ensimbi engagqwali agxiviziwe ayizinto ezihlukahlukene ezisetshenziselwa ukudala umphumela wokuhlobisa ebusweni bensimbi. Ziyinketho enhle kakhulu yamaphrojekthi wezakhiwo, ama-splashbacks, izimpawu, nokuningi. Zingasindi ngokwedlulele, futhi zingalolongwa ukuze zihlangabezane nezicaciso zezinhlelo zokusebenza ezihlukene. |

| Umbala | I-Coloured Steel iyinsimbi engagqwali ene-titanium. Imibala itholakala ngokusebenzisa inqubo ephuma ku-PVD. Amafomu ebusweni beshidi ngalinye ahlinzeka ngezinhlobo ezahlukene zokugqoka, njengama-oxides, ama-nitrides nama-carbides. |

Izici Zeshidi Lensimbi Engagqwali kanye Nepuleti

Ukusetshenziswa Okuyinhloko yizi

1. Ui-sed yokucubungula zonke izinhlobo zezingxenye ezijwayelekile kanye nokushaya isitembu;

2.Used njengoba high ngokunemba izingxenye mechanical of steel;

3. Isetshenziswa kakhulu ohlelweni lokwelashwa kokushisa lokunciphisa ukucindezeleka ngaphambi kokugoba.

4. Ingasetshenziswa njengempahla yokwakha yokwakha umphakathi.

7. Ingasetshenziswa embonini yezimoto.

8. Ingasetshenziswa embonini yemishini yasendlini. Umkhakha wamandla enuzi. Isikhala kanye nezindiza. Inkambu ye-elekthronikhi nekagesi. Imboni yemishini yezokwelapha. Imboni yokwakha imikhumbi.

Ukwakheka Kwekhemikhali Kwensimbi Engagqwali Evamile Esetshenziswayo

| Ibanga | C | Si | Mn | P | S | Ni | Cr | Mo | Abanye |

| 304 | ≤0.07 | ≤0.75 | ≤2.00 | ≤0.045 | ≤0.030 | 8.0/10.5 | 17.5/19.5 | ― | N≤0.10 |

| 304H | 0.04/0.10 | ≤0.75 | ≤2.00 | ≤0.045 | ≤0.030 | 8.0/10.5 | 18.0/20.0 | ― | |

| 304L | ≤0.030 | ≤0.75 | ≤2.00 | ≤0.045 | ≤0.030 | 8.0/12.0 | 17.5/19.5 | ― | N≤0.10 |

| 304N | ≤0.08 | ≤0.75 | ≤2.00 | ≤0.045 | ≤0.030 | 8.0/10.5 | 18.0/20.0 | ― | N:0.10/0.16 |

| 304LN | ≤0.030 | ≤0.75 | ≤2.00 | ≤0.045 | ≤0.030 | 8.0/12.0 | 18.0/20.0 | ― | N:0.10/0.16 |

| 309S | ≤0.08 | ≤0.75 | ≤2.00 | ≤0.045 | ≤0.030 | 12.0/15.0 | 22.0/24.0 | ― | |

| 310S | ≤0.08 | ≤1.50 | ≤2.00 | ≤0.045 | ≤0.030 | 19.0/22.0 | 24.0/26.0 | ― | |

| 316 | ≤0.08 | ≤0.75 | ≤2.00 | ≤0.045 | ≤0.030 | 10.0/14.0 | 16.0/18.0 | 2.00/3.00 | N≤0.10 |

| 316L | ≤0.030 | ≤0.75 | ≤2.00 | ≤0.045 | ≤0.030 | 10.0/14.0 | 16.0/18.0 | 2.00/3.00 | N≤0.10 |

| 316H | 0.04/0.10 | ≤0.75 | ≤2.00 | ≤0.045 | ≤0.030 | 10.0/14.0 | 16.0/18.0 | 2.00/3.00 | |

| 316LN | ≤0.030 | ≤0.75 | ≤2.00 | ≤0.045 | ≤0.030 | 10.0/14.0 | 16.0/18.0 | 2.00/3.00 | N:0.10/0.16 |

| 317L | ≤0.030 | ≤0.75 | ≤2.00 | ≤0.045 | ≤0.030 | 11.0/15.0 | 18.0/20.0 | 3.0/4.0 | N≤0.10 |

| 317LN | ≤0.030 | ≤0.75 | ≤2.00 | ≤0.045 | ≤0.030 | 11.0/15.0 | 18.0/20.0 | 3.0/4.0 | N:0.10/0.22 |

| 321 | ≤0.08 | ≤0.75 | ≤2.00 | ≤0.045 | ≤0.030 | 9.0/12.0 | 17.0/19.0 | ― | N≤0.10Ti:5ʷʢC+Nʣ/0.70 |

| 347 | ≤0.08 | ≤0.75 | ≤2.00 | ≤0.045 | ≤0.030 | 9.0/13.0 | 17.0/19.0 | ― | Inani:10ʷC/1.00 |

| 904L | ≤0.020 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.035 | 23.0/28.0 | 19.0/23.0 | 4.00/5.00 | N≤0.10Cu:1.0/2.0 |

-

201 304 Ishidi Lensimbi Engagqwali Yesibuko Esibukweni ku-S...

-

316L 2B Ishidi Lensimbi Engagqwali Elihloliwe

-

304 Izingcwecwe Zokuhlanganisa Ishidi Lensimbi Engagqwali Elinemibala

-

430 Ishidi Lensimbi Engagqwali Elibhoboziwe

-

Ishidi Lensimbi Engagqwali I-SUS304

-

201 J1 J3 J5 Ishidi Lensimbi Engagqwali

-

Amashidi Ensimbi Angenasici Anezimbobo

-

Ishidi Lensimbi Engagqwali Elinemibala ye-PVD 316

-

Isilinganiso esihle kakhulu se-SUS304 BA Stainless Steel Sheets

-

SUS316 BA 2B Umhlinzeki Wamashidi Ensimbi Engagqwali