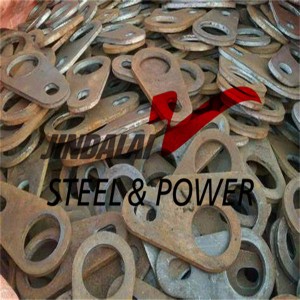

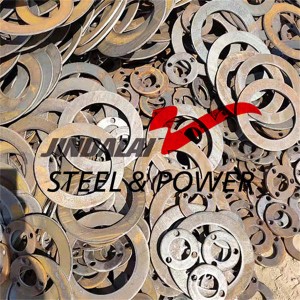

Ukucaciswa Kwezingxenye Zokugxiviza Zensimbi

| Igama Lomkhiqizo | Izingxenye Zezitembu Zensimbi ezenziwe ngezifiso |

| Okubalulekile | Insimbi, Insimbi Engagqwali, Aluminium, Ithusi, Ithusi, njll |

| Ukucwenga | I-Ni Plating, i-Sn Plating, i-Cr Plating, i-Ag Plating, i-Au Plating, upende we-electrophoretic njll. |

| Okujwayelekile | I-DIN GB ISO JIS BA ANSI |

| Dizayina ifomethi yefayela | Cad, jpg, pdf njll. |

| Imishini emikhulu | --AMADA Laser cutting machine --AMADA NCT punching machine --AMADA imishini yokugoba --TIG/MIG imishini yokushisela --Imishini yokushisela amabala --Imishini yokugxiviza (60T ~ 315T yenqubekelaphambili kanye no-200T~600T yokudlulisa irobhothi) -- Umshini wokugcwalisa --Umshini wokusika amapayipi --Isigayo sokudweba --Amathuluzi wokunyathela enza i-maaching(Umshini wokugaya we-CNC, i-Wire-cut, i-EDM, umshini wokugaya) |

| Cindezela ithoni yomshini | 60T to 315(Progress) kanye 200T~600T (Robot trensfer) |

Yini Izingxenye Ezigxiviziwe?

I-Stamping Parts-Stamping iyinqubo yokwakha encike emishinini yokunyathelisa futhi ifa ukuze isebenzise amandla angaphandle ezintweni ezifana namapuleti, imicu, amashubhu namaphrofayili ukuze kukhiqizwe ukuguqulwa kwepulasitiki noma ukuhlukaniswa ukuze kutholwe izingcezu zokusebenza zomumo nosayizi odingekayo (izingxenye ezinesitembu). Izikhala zokugxiviza ikakhulukazi amapuleti ensimbi agoqelwe ashisayo nagoqelwe ngokubanda. Ngenxa yokusetshenziswa kwe-precision dies, izingcezu zomsebenzi zingakhiqizwa ngokunemba kwezinga le-micron futhi ngokuphindaphinda okuphezulu nokufana kwezicaciso, okuvumela ukugxivizwa kwezimbobo nabaphathi, njll.

Izingxenye ezinesitembu zivame ukusetshenziswa ezimbonini ezahlukahlukene njengezezimoto, i-aerospace kanye nezokwelapha ukuhlinzeka ngezingxenye ezihlukahlukene ezenziwe ngokwezifiso. Izingxenye zensimbi ezinesitembu ziyindlela ephumelelayo nethengekayo yokuhlangabezana nezidingo zokwenziwa kwevolumu ephezulu yezingxenye zensimbi ezenziwe ngokwezifiso, ezihlangabezana nezidingo.

Izici Ze-Metal Stamping

Izingxenye ezinesitembu zinokunemba okuphezulu kobukhulu futhi izingxenye ezibunjiwe ezifanayo zinosayizi ofanayo. Bangakwazi ukuhlangabezana nomhlangano ojwayelekile futhi basebenzise izidingo ngaphandle kokucubungula okwengeziwe ngomshini.

Izingxenye ezinesitembu ezibandayo ngokuvamile azikho ngaphansi kwanoma iyiphi inqubo yokusika noma zidinga kuphela inani elincane lenqubo yokusika.

Enqubweni yokugxiviza, ingaphezulu lezinto ezibonakalayo alilimazi, ngakho-ke linekhwalithi enhle yendawo kanye nokubukeka okubushelelezi nokuhle, okunikeza izimo ezilula zokudweba kwendawo, i-electroplating, i-phosphating, i-powder spraying nokunye ukwelashwa kwendawo.

Izingxenye ezinesitembu zenziwe ngokugxiviza ngesisekelo sokuthi impahla ayidliwe kakhulu. Izingxenye zilula ngesisindo futhi zinokuqina okuhle, futhi ngemva kokuguqulwa kwepulasitiki kweshidi, isakhiwo sangaphakathi sensimbi sithuthukisiwe, ukuze amandla ezingxenye ezigxiviziwe ande.

Uma kuqhathaniswa nama-castings nama-forging, izingxenye ezinezitembu zinezici zobuncane, ukufana, ukukhanya namandla. Ukugxiviza kungakhiqiza izingcezu zomsebenzi ezinemigoqo eqinisayo, izimbambo, ama-undulations noma ama-flange okunzima ukuwakhiqiza ngezinye izindlela, ukuze kuthuthukiswe ukuqina kwawo.

Imininingwane Umdwebo