Okuqukethwe kwe-alloy ye-Chrome Moly Plate

I-Chrome moly plate ngaphansi kwe-ASTM A387 kumabanga ajwayelekile anokuqukethwe kwe-alloy okuhlukile njengoba ngezansi, amabanga okusetshenziswa okuvamile yi-Gr 11, 22, 5, 9 kanye no-91.

Ngaphandle kuka-21L, 22L kanye no-91, ibanga ngalinye litholakala ngezigaba ezimbili zamazinga wamandla aqinile njengoba kuchazwe kumathebula ezidingo ze-tensile. Amabanga 21L no-22L aneClass 1 kuphela, kanti iBanga 91 lineClass2 kuphela.

| Ibanga | Okuqukethwe kwe-Chromium Okuncane, % | Okuqukethwe kwe-Molybdenum Okungaziwa, % |

| 2 | 0.50 | 0.50 |

| 12 | 1.00 | 0.50 |

| 11 | 1.25 | 0.50 |

| 22, 22l | 2.25 | 1.00 |

| 21, 21L | 3.00 | 1.00 |

| 5 | 5.00 | 0.50 |

| 9 | 9.00 | 1.00 |

| 91 | 9.00 | 1.00 |

Amazinga Abhekwayo we-ASTM A387 Alloy Steel Plate ASTM

I-A20/A20M: Izidingo ezijwayelekile zamapuleti emikhumbi yomfutho.

I-A370: Ukucaciswa kokuhlolwa kwezakhiwo zensimbi

I-A435/A435M: Ukuze uthole ukuhlolwa kwe-ultrasonic okuqondile kwamapuleti ensimbi.

I-A577/A577M: Ukuze kuhlolwe i-ultrasonic angle beam yamapuleti ensimbi.

I-A578/A578M: Ukuze uthole ukuhlolwa kwe-UT okuqondile kwamapuleti ensimbi agingqelwe ezinhlelweni ezikhethekile.

I-A1017/A1017M: Ukucaciswa kwamapuleti e-vessle yokucindezela ensimbi ye-alloy, i-chromium-molybdenum-tungsten.

Ukucaciswa kwe-AWS

I-A5.5/A5.5M: Ama-electrode ensimbi ye-alloy ephansi yokushisela i-arc yensimbi yesihlangu.

I-A5.23/A5.23M: Ama-electrode ensimbi ye-alloy ephansi yama-fulxes wokushisela i-arc engaphansi.

I-A5.28/A5.28M: Okokushisela i-arc evikelwe ngegesi.

I-A5.29/A5.29M: Okwe-flux cored arc welding.

Ukwelashwa Kokushisa kwe-A387 Chrom Moly Alloy Steel Plate

Ipuleti lensimbi le-Chrome moly alloy ngaphansi kwe-ASTM A387 lizobulawa insimbi, futhi liphathwe ngokushisa okuphakathi, ukujwayela nokufudumeza. Noma uma kuvunyelwa umthengi, ukupholisa okusheshisiwe kusuka kuzinga lokushisa eliqinile ngokuqhunyiswa komoya noma ukucisha uketshezi, okulandelwa ukushisa, amazinga okushisa amancane azoba njengalokhu ngezansi kwethebula:

| Ibanga | Izinga lokushisa, °F [°C] |

| 2, 12 kanye ne-11 | 1150 [620] |

| 22, 22L, 21, 21L kanye no-9 | 1250 [675] |

| 5 | 1300 [705] |

Amapuleti ensimbi ye-alloy yeBanga lama-91 kufanele aphathwe ngokushisisa ngokujwayela nokufudumeza noma ngokupholisa okusheshisiwe ngokuqhunyiswa komoya noma ukucisha uketshezi, okulandelwa ukufudumeza. Amapuleti eBanga lesi-91 adinga ukuqinisekiswa ku-1900 kuya ku-1975°F [1040 kuya ku-1080°C] futhi azoshiswa ku-1350 kuya ku-1470°F [730 kuya ku-800°C]

Ibanga lesi-5, 9, 21, 21L, 22, 22L, kanye namapuleti angu-91 a-odwe ngaphandle kokwelashwa ngokushisa ngethebula elingenhla, azoqedwa esimweni sokukhululeka noma sokuncibilika.

Imininingwane yokudweba

-

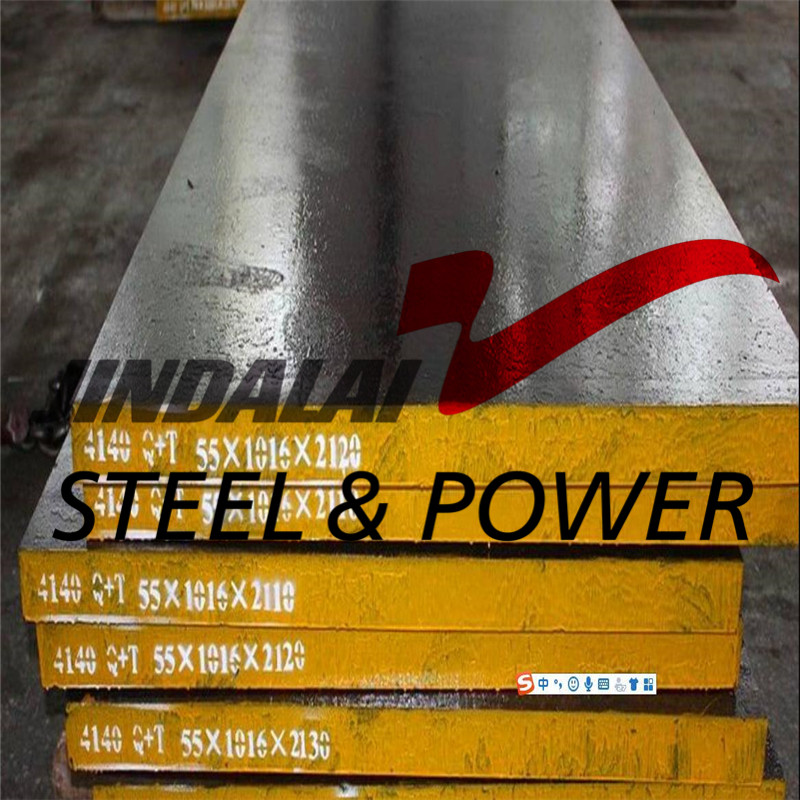

I-4140 Alloy Steel Plate

-

I-Nickel 200/201 I-Nickel Alloy Plate

-

I-Nickel Alloy Plates

-

I-ASTM A36 Steel Plate

-

I-Checkered Steel Plate

-

I-AR400 Steel Plate

-

Amapuleti Ensimbi Amelana Nomhuzuko

-

I-516 Grade 60 Vessel Steel Plate

-

I-Boiler Steel Plate

-

I-Pipeline Steel Plate

-

I-S235JR Carbon Steel Plates/MS Plate

-

I-S355 Structural Steel Plate

-

I-Steel Plate yokwakha umkhumbi

-

I-SA516 GR 70 Izingcwecwe Zensimbi Yomshini Wokucindezela

-

I-ST37 Steel Plate/ I-Carbon Steel Plate