Ibanga Le-High Steel Carbon Plate

| I-ASTM A283/A283M | I-ASTM A573/A573M | ASME SA36/SA36M |

| ASME SA283/SA283M | ASME SA573/SA573M | I-EN10025-2 |

| I-EN10025-3 | I-EN10025-4 | EN10025-6 |

| I-JIS G3106 | I-DIN 17100 | I-DIN 17102 |

| I-GB/T16270 | I-GB/T700 | I-GB/T1591 |

Thatha Izicelo ze-A36 Njengesibonelo

Ukusetshenziswa kwe-ASTM A36 Carbon Structural Steel Plate

| Izingxenye Zomshini | Amafreyimu | Ukulungiswa | Ukuthwala Amapuleti | Amathangi | Imigqomo | Ukuthwala Amapuleti | Forgings |

| Amapuleti ayisisekelo | Amagiya | Amakhamera | Ama-Sprockets | Amajiki | Izindandatho | Izifanekiso | Ukulungiswa |

| Izinketho Zokwenziwa Kwepuleti Lensimbi le-ASTM A36 | |||||||

| Ukugoba Okubandayo | Ukwakheka Okushisayo Okumaphakathi | Ukubhoboza | Ukwenza imishini | Ukushisela | Ukugoba Okubandayo | Ukwakheka Okushisayo Okumaphakathi | Ukubhoboza |

Ukubunjwa Kwekhemikhali kwe-A36

| I-ASTM A36 Ipuleti Lensimbi Eligoqiwe Elishisayo | I-Chemical Compostion | |

| Isici | okuqukethwe | |

| Carbon, C | 0.25 - 0.290 % | |

| Copper, Ku | 0.20 % | |

| Iron, Fe | 98.0 % | |

| IManganese, Mn | 1.03 % | |

| I-Phosphorous, P | 0.040 % | |

| Silicon, Si | 0.280 % | |

| Isibabule, S | 0.050 % | |

Impahla Ephathekayo ye-A36

| Impahla Engokomzimba | Imethrikhi | I-Imperial |

| Ukuminyana | 7.85 g/cm3 | 0.284 lb/ku-3 |

Isakhiwo sikaMechanical se-A36

| I-ASTM A36 Ipuleti Lensimbi Eligoqiwe Elishisayo | ||

| Izakhiwo Zemishini | Imethrikhi | I-Imperial |

| Amandla Aqinile, Okugcina | 400 - 550 MPa | 58000 - 79800 psi |

| Amandla Aqinile, Yield | 250 MPa | Idatha ye-36300 |

| I-Elongation at Break (ku-200 mm) | 20.0 % | 20.0 % |

| Ukwelulwa ngesikhathi sekhefu (ku-50 mm) | 23.0 % | 23.0 % |

| I-Modulus ye-Elasticity | 200 GPA | 29000 nxa |

| I-Bulk Modulus (ejwayelekile yensimbi) | 140 GPA | 20300 k |

| Poissons Isilinganiso | 0.260 | 0.260 |

| Shear Modulus | 79.3 GPA | 11500 k |

I-Carbon steel iyingxubevange ehlanganisa insimbi ne-carbon. Ezinye izakhi eziningana zivunyelwe ku-carbon steel, ngamaphesenti aphansi aphezulu. Lezi zakhi ziyi-manganese, enobukhulu obungu-1.65%, i-silicon, enobukhulu obungu-0.60%, nethusi, enobukhulu obungu-0.60%. Ezinye izakhi zingase zibe khona ngamanani amancane kakhulu ukuthi zingathinta izici zayo.

Kunezinhlobo ezine zensimbi ye-carbon

Ngokusekelwe enanini lekhabhoni elikhona ku-alloy. Izinsimbi zekhabhoni ephansi zithambile futhi zakheka kalula, futhi izinsimbi ezinokuqukethwe kwekhabhoni ephezulu ziba lukhuni futhi ziqine, kodwa zincane i-ductile, futhi ziba nzima kakhulu ukuwenza umshini nokushisela. Ngezansi izakhiwo zamamaki e-carbon steel esiwahlinzekayo:

● I-Carbon Steel Ephansi–Ukwakheka kuka-0.05% -0.25% wekhabhoni futhi kufika ku-0.4% manganese. Eyaziwa nangokuthi insimbi emnene, iyimpahla ebiza kancane okulula ukuyibumba. Nakuba kungenzima njengezinsimbi zekhabhoni ephezulu, ukungcwatshwa kwemoto kungakhuphula ubulukhuni bayo bobuso.

● Insimbi Yekhabhoni Emaphakathi – Ukwakhiwa kwekhabhoni engu-0.29% -0.54%, ne-0.60% -1.65% manganese. I-Medium carbon steel iyi-ductile futhi iqinile, inezinto ezigqokwa isikhathi eside.

● I-High Carbon Steel– Ukwakheka kuka-0.55% -0.95% wekhabhoni, ne-0.30% -0.90% manganese. Inamandla kakhulu futhi ibamba inkumbulo yomumo kahle, iyenza ilungele iziphethu nocingo.

● Insimbi Yekhabhoni Ephakeme Kakhulu - Ukwakhiwa kwekhabhoni engu-0.96% -2.1%. Okuqukethwe kwayo kwekhabhoni ephezulu kuyenza ibe yinto eqinile kakhulu. Ngenxa yokuqina kwalo, leli banga lidinga ukuphathwa okukhethekile.

Imininingwane yokudweba

-

I-A36 Hot Rolled Steel Plate Factory

-

Q345, A36 SS400 Ikhoyili Yensimbi

-

I-ASTM A36 Steel Plate

-

I-ASTM A653 Z275 Ikhoyili Yensimbi Yakhandiwe yaseChina Factory

-

I-S355 Structural Steel Plate

-

I-Offshore Steel Plate ye-S355G2

-

S355J2W Corten Plates Weathering Steel Plates

-

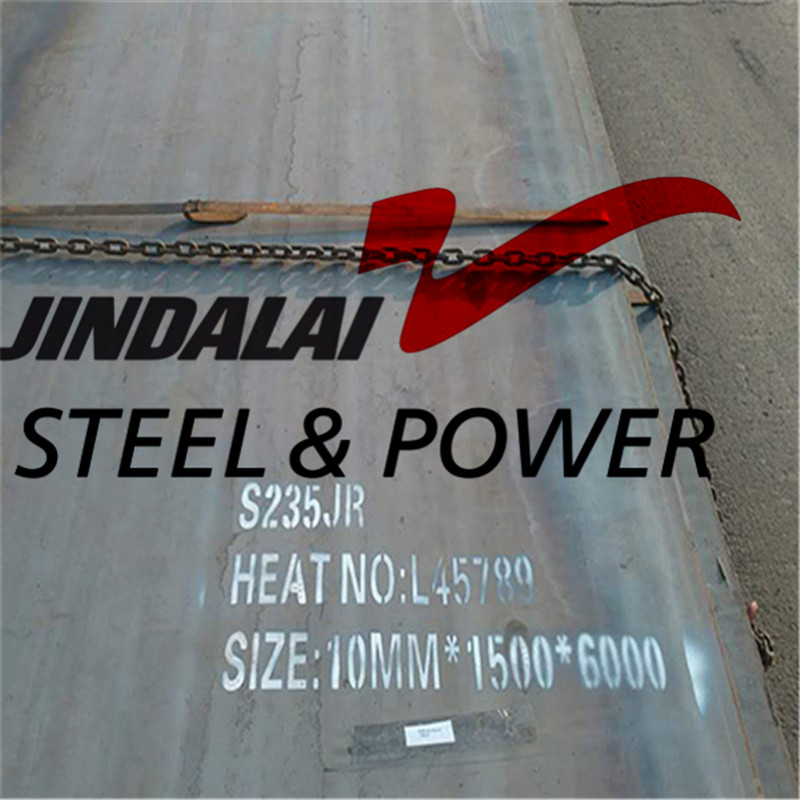

I-S235JR Carbon Steel Plates/MS Plate

-

I-SS400 Q235 ST37 Ikhoyili Yensimbi Egingqiwe Eshisayo

-

I-Checkered Steel Plate

-

Ipuleti Lensimbi Eligoqiwe Elinothayela Elibomvu

-

IPEDI ELITHIWEKWE LESsimbi ELIPHAKATHI (MS)

-

Ikhoyili Egingqiwe Yokuhlola Eshisayo/UNksz Checkered Coils/HRC