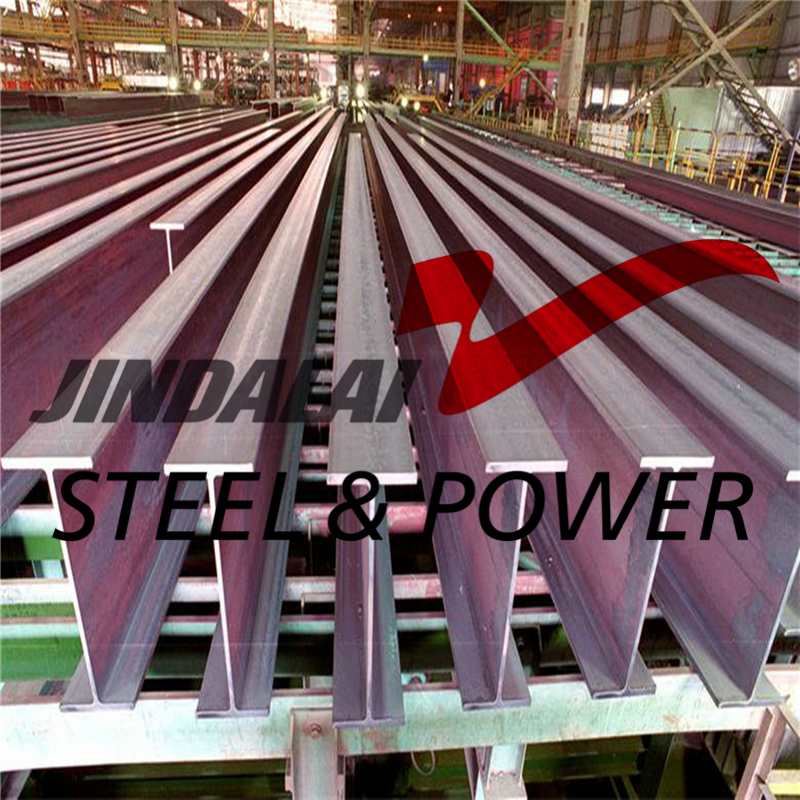

Uhlolojikelele lwe-ASTM A36 H Beam

Insimbi ye-ASTM A36 Hiyinsimbi enekhabhoni ephansi ekhombisa amandla amahle ahambisana nokwakheka. Kulula ukuwenza ngomshini nokwenza futhi ungashiselwa ngokuphephile. Insimbi ye-A36 H ingafakwa uthayela ukuze inikeze ukumelana nokugqwala okwandisiwe. Amandla okukhiqiza e-ASTM A36 angaphansi kwalawo e-cold roll C1018, ngaleyo ndlela enze i-ASTM A36 ikwazi ukugoba kalula kune-C1018. Imvamisa, ama-diameter amakhulu ku-ASTM A36 awakhiqizwa njengoba kusetshenziswa imijikelezo ye-C1018 hot roll.

Ukucaciswa kwe-ASTM A36 H Beam

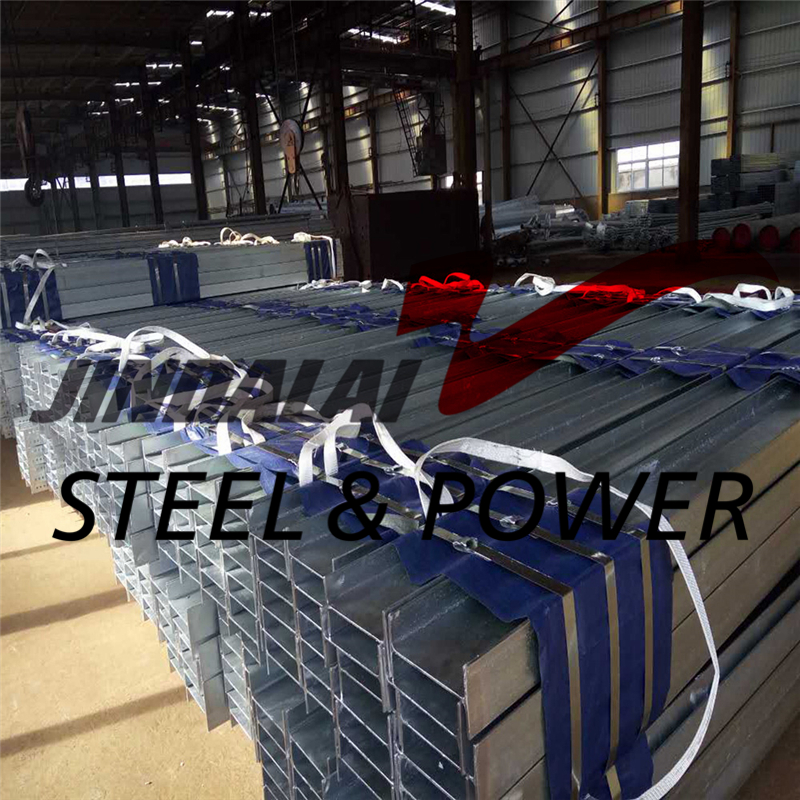

| Okujwayelekile | I-TS EN 10219 Izingxenye Zezinsimbi Ezingeyona Ingxubevange kanye Nezinsimbi Ezinhle Ezakhiwe Okushiselwe Ezakhiwe Okushiselwe |

| Ibanga | I-S235JRH |

| Ama-SHS (Izingqimba Eziyisikwele) Osayizi | 20*20mm-400*400mm |

| Ukuqina Kwezindonga | 0.5mm - 25mm |

| Ubude | 6000-14000 mm |

| Uhlobo | Ingenamthungo/ Eshiselwe / ERW |

| Ukupakisha | Ezinyangeni, Anti-ukugcinwa kokushisa kwe-corrosion, i-varnish coating, Iziphetho zingafakwa nge-bevelled noma zisikwe isikwele, Isitifiketi Sokuqeda Isitifiketi Nokuhlolwa okungeziwe, Ukuqeda & Umazisi |

| I-Surface Protection | Mnyama (Okunombala Ozimele), I-varnish/I-Oil Coating, I-Pre-Galvanized, Idiphu Eshisayo Eshisiwe |

Ukubunjwa Kwekhemikhali Kwezakhiwo Zensimbi ze-A36

| I-A36 Material Chemical Composition (%, ≤), Yamapuleti, Ububanzi > 380 mm (15 in.) | |||||||||||||

| Insimbi | C | Si | Mn | P | S | Cu | Ubukhulu (d), mm (in.) | ||||||

| I-ASTM A36 | 0.25 | 0.40 | akukho mfuneko | 0.03 | 0.03 | 0.20 | d ≤20 (0.75) | ||||||

| 0.25 | 0.40 | 0.80-1.20 | 0.03 | 0.03 | 0.20 | 20 | |||||||

| 0.26 | 0.15-0.40 | 0.80-1.20 | 0.03 | 0.03 | 0.20 | 40 | |||||||

| 0.27 | 0.15-0.40 | 0.85-1.20 | 0.03 | 0.03 | 0.20 | 65 | |||||||

| 0.29 | 0.15-0.40 | 0.85-1.20 | 0.03 | 0.03 | 0.20 | > 100 (4) | |||||||

| I-A36 Material Chemical Composition (%, ≤), Yamapuleti namabha, Ububanzi ≤ 380 mm (15 in.) | |||||||||||||

| Insimbi | C | Si | Mn | P | S | Cu | Ubukhulu (d), mm (in.) | ||||||

| I-ASTM A36 | 0.26 | 0.40 | akukho mfuneko | 0.04 | 0.05 | 0.20 | d ≤ 20 (0.75) | ||||||

| 0.27 | 0.40 | 0.60-0.90 | 0.04 | 0.05 | 0.20 | 20< d≤ 40 (0.75< d≤ 1.5) | |||||||

| 0.28 | 0.40 | 0.60-0.90 | 0.04 | 0.05 | 0.20 | 40< d≤ 100 (1.5< d≤ 4) | |||||||

| 0.29 | 0.40 | 0.60-0.90 | 0.04 | 0.05 | 0.20 | > 100 (4) | |||||||