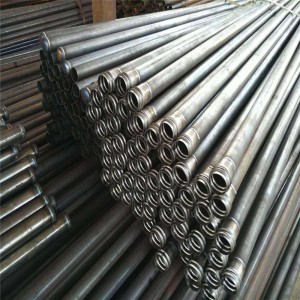

Uhlolojikelele lwe-Crosshole Sonic Logging (CSL) Pipe

Amashubhu e-CSL avamise ukukhiqizwa ngobubanzi obungu-1.5- noma 2-intshi, agcwaliswe amanzi, futhi acushwe ngamakepisi nama-couplers angangeni manzi. Lokhu kuqinisekisa ukuthi amashubhu athobelana nemibandela ye-American Society of Testing and Materials (ASTM)-A53 Grade B, kanye nemibiko yokuhlolwa komshini (MTR). Lawa mashubhu ngokuvamile anamathiselwe ku-rebar cage eqinisa i-shaft ebhoboziwe.

Ukucaciswa kwe-Cross Hole Sonic Logging (CSL) Tubes

| Igama | Isikulufa/I-Auger Type Sonic Log Pipe | |||

| Isimo | Ipayipi elingu-1 | No.2 ipayipi | No.3 ipayipi | |

| Ububanzi bangaphandle | 50.00mm | 53.00mm | 57.00mm | |

| Ukujiya kodonga | 1.0-2.0mm | 1.0-2.0mm | 1.2-2.0mm | |

| Ubude | 3m/6m/9m, njll. | |||

| Okujwayelekile | I-GB/T3091-2008, ASTM A53, BS1387, ASTM A500, BS 4568, BS EN31, DIN 2444, njll. | |||

| Ibanga | Ibanga laseShayina | Q215 Q235 Ngokusho GB/T700;Q345 Ngokusho kwe-GB/T1591 | ||

| Ibanga langaphandle | I-ASTM | A53, Grade B, Grade C, Grade D, Grade 50 A283GRC, A283GRB, A306GR55, njll | ||

| EN | I-S185, S235JR, S235J0, E335, S355JR, S355J2, njll. | |||

| I-JIS | SS330, SS400, SPFC590, njll | |||

| Ubuso | I-Bared, Galvanized, Oiled, Color Paint, 3PE; Noma Okunye Ukwelashwa Kwe-Anti-corrosive | |||

| Ukuhlola | Ngokuhlaziywa Kwamakhemikhali Nokuhlaziywa Kwezakhiwo Zemishini; Ukuhlolwa Kobukhulu Nokubonakalayo, Futhi Ngokuhlola Okungonakali. | |||

| Ukusetshenziswa | Isetshenziswa ezinhlelweni zokuhlola ze-sonic. | |||

| imakethe enkulu | Middle East, Africa, Asia kanye nezwe elithile laseYurophu, America, Australia | |||

| Ukupakisha | 1.inqwaba 2.ngobuningi 3.izikhwama zepulasitiki 4.ngokwemfuneko yeklayenti | |||

| Isikhathi sokuthumela | Izinsuku eziyi-10-15 ngemuva kokuqinisekiswa kwe-oda. | |||

| Imigomo Yokukhokha | 1.T/T 2.L/C: ngokubona 3.Westem Union | |||

Izicelo ze-Cross Hole Sonic Logging (CSL) Tubes

Amashubhu ngokuvamile anamathele ekhejini lokuqinisa eduze nobude obugcwele be-shafts. Ngemva kokuthelwa ukhonkolo, amashubhu agcwaliswa ngamanzi. Ku-CSL, isidlulisi sikhipha isignali ye-ultrasonic eshubhuni elilodwa futhi isignali izwakala esikhathini esithile kamuva umamukeli kwelinye ishubhu le-sonic. Ukhonkolo ompofu phakathi kwamashubhu e-sonic uzobambezela noma aphazamise isignali. Unjiniyela wehlisa ama-probe phansi kwe-shaft bese ehambisa isidluliseli nomamukeli phezulu, kuze kube yilapho bonke ubude be-shaft buskenwa. Unjiniyela uphinda ukuhlolwa kwepheya ngalinye lamashubhu. Unjiniyela utolika idatha endaweni futhi kamuva ayicubungule ehhovisi.

Amapayipi e-JINDALAI e-CSL akhiwe ngensimbi. Amapayipi ensimbi ngokuvamile akhethwa ngaphezu kwamapayipi e-PVC ngoba impahla ye-PVC ingaxhunywa kukhonkolo ngenxa yokushisa okuvela kwinqubo ye-concrete hydration. Amapayipi aboshiwe ngokuvamile aholela emiphumeleni yokuhlolwa kukakhonkolo engahambisani. Amapayipi ethu e-CSL avame ukusetshenziswa njengesinyathelo sokuqinisekisa ikhwalithi ukuze kuqinisekiswe ukuzinza kwezisekelo zeshafti ezibhobhile kanye nobuqotho besakhiwo. Amapayipi ethu e-CSL enziwe ngendlela oyifisayo angasetshenziswa futhi ukuhlola izindonga eziludaka, izinqwaba ze-auger cast, izisekelo zomata, kanye nokuthululwa kukakhonkolo omkhulu. Lolu hlobo lokuhlola lungenziwa futhi ukuze kunqunywe ubuqotho bomgodi obhobhile ngokuthola izinkinga ezingaba khona njengokugxambukela kwenhlabathi, amalensi esihlabathi, noma izikhala.

Izinzuzo ze-Cross Hole Sonic Logging (CSL) Tubes

1.Fast futhi kulula ukufakwa isisebenzi.

2.Push-fit inhlangano.

3.Akukho ukushisela okudingekayo endaweni yomsebenzi.

4.Akukho mishini edingekayo.

5.Ukulungiswa okulula kwekheji le-rebar.

6.I-Push-fit mark ukuze uqinisekise ukuhlanganyela okugcwele.

-

I-A53 Grouting Steel Pipe

-

I-API5L Carbon Steel Pipe/ERW Pipe

-

I-ASTM A53 yeBanga A & B Ipayipi Lensimbi ERW Ipayipi

-

I-ASTM A536 Ductile Iron Tube

-

I-A106 Crosshole Sonic Logging Welded Tube

-

ASTM A53 Crosshole Sonic Logging (CSL) Welded Pipe

-

I-SSAW Steel Pipe/Spiral Weld Pipe

-

I-A106 GrB Seamless Grouting Steel Pipes for Pile

-

Ihange Lomjovo Lokujova Elingenalutho lika-R25...