Uhlolojikelele lwepayipi yensimbi ye-alloy

Ipayipi Lensimbi Lengxubevange lisetshenziswa ezinhlelweni ezidinga izakhiwo zokumelana nokugqwala okusesilinganisweni ezihlala isikhathi eside futhi ngezindleko ezongayo. Ukukubeka nje, amapayipi e-alloy akhethwa kulezo zindawo lapho amapayipi ensimbi e-carbon angase ahluleke. Kunezigaba ezimbili zezinsimbi ze-alloy - ama-alloys aphezulu nezinsimbi eziphansi ze-alloy. Amapayipi akha ama-low alloy steels anokuqukethwe kwe-alloying okungaphansi kuka-5%. Nakuba okuqukethwe kwe-alloying yensimbi ephezulu ye-alloy kungaba phakathi kuka-5% kuya cishe ku-50%. Ngokufana nama-alloy amaningi amandla okucindezela okusebenzayo kwepayipi lensimbi engenasici licishe libe ngama-20% ngaphezu kwepayipi elishiselwe. Ngakho-ke ezinhlelweni ezinomfutho ophakeme wokusebenza njengemfuneko, ukusetshenziswa kwepayipi elingenamthungo kuyafaneleka. Nakuba linamandla kunepayipi elishiselwe, izindleko ziphakeme kakhulu. Ngaphezu kwalokho, ubungozi bokugqwala kwe-intergranular endaweni yokushisela ethintekile kumkhiqizo oshiselwe kakhulu. Umehluko obonakalayo phakathi kwe-Alloy Steel Welded Pipe kanye nomkhiqizo ongenamthungo umthungo we-latitudinal ngobude bepayipi. Kodwa-ke, namuhla, ngokuthuthuka kwezobuchwepheshe, umthungo okhona ku-Alloy Steel ERW Pipe ungancishiswa kakhulu ngendlela yokwelapha ngaphezulu, ukuze uhlale ungabonakali emehlweni abantu.

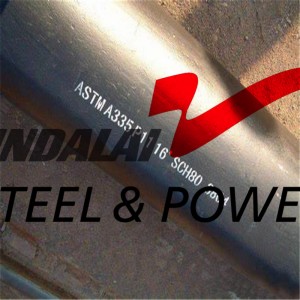

Ishubhu yensimbi ye-alloy & Ukucaciswa Kwepayipi (Okungenamthungo/ Okushiselwe/ ERW)

| Imininingwane | I-ASTM A 335 ASME SA 335 |

| Okujwayelekile | ASTM, ASME kanye API |

| Usayizi | 1/8" NB UKUYA KU-30" QAPHELA |

| Usayizi we-Tubing | 1 / 2" OD kufika ku-5" OD, amadayamitha wamasiko nawo ayatholakala |

| Ububanzi bangaphandle | 6-2500mm; WT: 1-200mm |

| Isheduli | SCH20, SCH30, SCH40, STD, SCH80, XS, SCH60, SCH80, SCH120, SCH140, SCH160, XXS |

| Ibanga | I-STM A335 Gr. P5, P9, P11, P12, P21, P22 & P91, ASTM A213 – T5, T9, T11, T12, T22, T91, ASTM A691 |

| Ubude | Ngaphakathi 13500mm |

| Uhlobo | Ingenamthungo / Yenziwe |

| Ifomu | Umjikelezo, Hydraulic Etc |

| Ubude | Okungahleliwe Okukodwa, Okungahleliwe Okuphindwe Kabili & Nobude Besika. |

| Qeda | I-Plain End, I-Beveled End, Inyathelwe |

Izinhlobo ze-Alloy Steel Seamless Tubes

15cr mo ingxubevange amapayipi ensimbi eqinile

Ipayipi yensimbi engu-25crmo4

36 intshi ASTM A 335 Grade P11 ingxubevange ipayipi galvanized steel

42CrMo/SCM440 ingxubevange yensimbi ipayipi nekhono

Ingxubevange 20/21/33 steel pipe

40MM ipayipi ingxubevange steel

I-ASTM A355 P22 Ipayipi Lensimbi Elingenamthungo

I-ASTM A423 Alloy Steel Pipe engenamthungo

Ipayipi lensimbi elakhiwe ngamapulangwe aphansi

I-alloy Steel ERW Pipes Chemical Properties

| I-alloy Steel | |||||||

| C | Cr | Mn | Mo | P | S | Si | |

| 0.05 - 0.15 | 1.00 - 1.50 | 0.30 - 0.60 | 0.44 – 0.65 | 0.025 ubuningi | 0.025 ubuningi | 0.50 - 1.00 |

Mechanical Characteristics Alloy Steel Chrome moly Pipes

| Amandla Okuqina, MPa | Isivuno Amandla, MPa | Ubude, % |

| 415 imiz | 205 imiz | 30 imiz |

Ngaphandle Ububanzi & Ukubekezelelana kwe-ASME SA335 Alloy Pipe

| I-ASTM A450 | Okushisayo kugoqiwe | Ngaphandle Ububanzi, mm | Ukubekezela, mm |

| OD≤101.6 | +0.4/-0.8 | ||

| 101.6<OD≤190.5 | +0.4/-1.2 | ||

| 190.5<OD≤228.6 | +0.4/-1.6 | ||

| Okubandayo Okudwetshiwe | Ngaphandle Ububanzi, mm | Ukubekezela, mm | |

| OD<25.4 | ±0.10 | ||

| 25.4≤OD≤38.1 | ±0.15 | ||

| 38.1<OD<50.8 | ±0.20 | ||

| 50.8≤OD<63.5 | ±0.25 | ||

| 63.5≤OD<76.2 | ±0.30 | ||

| 76.2≤OD≤101.6 | ±0.38 | ||

| 101.6<OD≤190.5 | +0.38/-0.64 | ||

| 190.5<OD≤228.6 | +0.38/-1.14 | ||

| I-ASTM A530 ne-ASTM A335 | I-NPS | Ngaphandle Ububanzi, iyintshi | Ukubekezela, mm |

| 1/8≤OD≤1-1/2 | ±0.40 | ||

| 1-1/2<OD≤4 | ±0.79 | ||

| 4<OD≤8 | +1.59/-0.79 | ||

| 8<OD≤12 | +2.38/-0.79 | ||

| OD>12 | ±1% |

Ingxubevange Steel Ibanga Amapayipi Ukushisa Ukwelashwa

| I-P5, i-P9, i-P11, ne-P22 | |||

| Ibanga | Uhlobo Lokwelapha Ukushisa | Ibanga Lezinga lokushisa Elijwayelekile F [C] | I-Subcritical Annealing noma Ukushisa Ibanga lokushisa F [C] |

| I-P5 (b,c) | I-Aneal egcwele noma ye-Isothermal | ||

| Normalize futhi Uthukuthele | ***** | 1250 [675] | |

| I-Subcritical Anneal (P5c kuphela) | ***** | 1325 - 1375 [715 - 745] | |

| P9 | I-Aneal egcwele noma ye-Isothermal | ||

| Normalize futhi Uthukuthele | ***** | 1250 [675] | |

| P11 | I-Aneal egcwele noma ye-Isothermal | ||

| Normalize futhi Uthukuthele | ***** | 1200 [650] | |

| P22 | I-Aneal egcwele noma ye-Isothermal | ||

| Normalize futhi Uthukuthele | ***** | 1250 [675] | |

| P91 | Normalize futhi Uthukuthele | 1900-1975 [1040 - 1080] | 1350-1470 [730 - 800] |

| Qeda futhi Uthukuthele | 1900-1975 [1040 - 1080] | 1350-1470 [730 - 800] |

I-alloy Steel Seamless Application Industries

● Izinkampani Zokumba Amafutha E-Off-Shore

● Ukukhiqiza Amandla

● Amakhemikhali kaphethroli

● Ukucutshungulwa Kwegesi

● Amakhemikhali Akhethekile

● Imithi

● Izisetshenziswa Zemithi

● Izisetshenziswa Zamakhemikhali

● Izisetshenziswa Zamanzi Zasolwandle

● Izishintshi Zokushisa

● Ama-condenser

● Imboni ye-Pulp nephepha

Imininingwane yokudweba

-

4140 Alloy Steel Tube & AISI 4140 Pipe

-

I-ASTM A335 Alloy Steel Pipe 42CRMO

-

I-A106 GrB Seamless Grouting Steel Pipes for Pile

-

I-A53 Grouting Steel Pipe

-

I-API5L Carbon Steel Pipe/ERW Pipe

-

I-ASTM A53 yeBanga A & B Ipayipi Lensimbi ERW Ipayipi

-

FBE ipayipi/epoxy camera steel ipayipi

-

Ipayipi Eliphezulu Lensimbi Enembile

-

I-Hot Dip Galvanized Steel tube/GI Pipe

-

I-SSAW Steel Pipe/Spiral Weld Pipe

-

Ipayipi Lensimbi Engagqwali