Iyini i-Abrasion Resistant Steel Plates

Ipuleti lensimbi elimelana ne-abrasion (AR).iyi-high-carbon alloy steel plate. Lokhu kusho ukuthi i-AR inzima ngenxa yokwengezwa kwekhabhoni, futhi iyakheka futhi imelana nesimo sezulu ngenxa yama-alloys angeziwe.

Ikhabhoni engezwe ngesikhathi kwakhiwa ipuleti lensimbi inyusa kakhulu ukuqina nokuqina kodwa inciphisa amandla. Ngakho-ke, ipuleti le-AR lisetshenziswa ezinhlelweni lapho imihuzuko kanye nokuguga kuyimbangela enkulu yokwehluleka, njengokukhiqizwa kwezimboni, izimayini, ukwakhiwa kanye nokuphatha impahla. Ipuleti le-AR alilungile ekusetshenzisweni kwesakhiwo njengemishayo yokusekela kumabhuloho noma izakhiwo.

Insimbi Engazweli I-Jindalai Ingakwazi Ukuhlinzeka

| I-AR200 |

| Insimbi ye-AR200 iyipuleti lensimbi elimelana nemihuzuko. Yinsimbi ye-medium-carbon manganese enobunzima obumaphakathi be-212-255 Brinell Hardness. I-AR200 ingafakwa ngomshini, ishaywe ngesibhakela, ibholwe futhi yakheke futhi yaziwa njengento engabizi ekwazi ukumelana nemihuzuko. Izicelo ezijwayelekile zingama-chute wezinto ezibonakalayo, izingxenye ezinyakazayo, amalayini wamaloli. |

| AR235 |

| I-AR235 carbon steel plate inobunzima obungajwayelekile be-235 Brinell Hardness. Le nsimbi yensimbi ayihloselwe ukusetshenziswa kwesakhiwo, kodwa ihloselwe ukugqoka okuphakathi. Ezinye izinhlelo zokusebenza ezijwayelekile ukuphatha impahla eyinqwaba ama-chute liner, ama-skirt board liner, izigubhu zokuhlanganisa usimende namaphiko, kanye namaconveyors ngezikulufu. |

| I-AR400 AR400F |

| Insimbi ye-AR400 yakhelwe ukuhuzuka nezinhlelo zokusebenza ezingagugi. Amamaki ensimbi ye-high-carbon alloy anqunywa ngobulukhuni bensimbi. Ipuleti lensimbi le-AR400 livamise ukusetshenziswa ezinhlelweni lapho imelana nemihuzuko, ukwakheka, nokushisela okudingekayo. Ezinye izimboni ezijwayelekile ezezimayini, okokusebenza okuphathekayo, kanye nokuhlanganisa. |

| I-AR450 AR450F |

| I-AR450 steel plate iyingxubevange eyakhiwe ngezinto ezihlukene, okuhlanganisa ikhabhoni ne-boron. Inikeza ubulukhuni obuningi kunepuleti lensimbi le-AR400 ngenkathi igcina ukwakheka okuhle, i-ductility, kanye nokumelana nomthelela. Ngakho-ke, isetshenziswa kakhulu ekugqokeni okumaphakathi kuya kokusindayo njengezinto zamabhakede, izinto zokwakha, namaloli omzimba wokulahla. |

| I-AR500 AR500F |

| I-AR500 steel plate iyingxubevange yensimbi enekhabhoni ephezulu futhi inokuqina kwendawo okungu-477-534 Brinell Hardness. Lokhu kwanda kwamandla nokumelana nokuhuzuka kunikeza umthelela omkhulu kanye nokumelana nokuslayida kodwa kuzokwenza insimbi ingabi namandla. I-AR500 ingamelana nokuguga nokuhuzuka, kokubili ukuthuthukisa impilo ende yemishini nokwandisa isikhathi sokukhiqiza. Izimboni ezijwayelekile ezezimayini, ukuphatha impahla, isamba, amaloli okulahla, amashutha okudlulisa impahla, imigqomo yokugcina, ama-hopper, namabhakede. |

| I-AR600 |

| I-AR600 steel plate iyipuleti eliqinile elimelana nokuhuzuka elinikezwa i-Jindalai Steel. Ngenxa yokumelana kwayo nokuhuzuka okuhle, ilungele ukuguga ngokweqile. Ukuqina kobuso be-AR600 kungu-570-640 Brinell Hardness futhi kuvame ukusetshenziswa ezimayini, ukususwa okuhlanganisiwe, ibhakede, kanye nezicelo zokugqoka okuphezulu. |

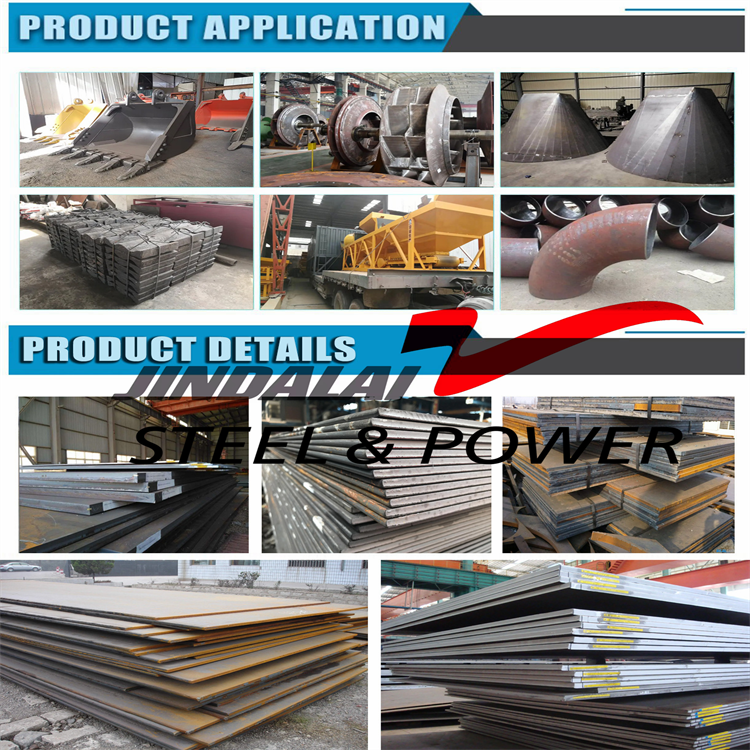

Insimbi ye-AR isetshenziselwa ukusiza ukumelana nokuguga nokuklebhuka okuhlanganisa

Ama-Conveyors

Amabhakede

Lahla amalayini

Izinamathiselo zokwakha, njengalezo ezisetshenziswa kumagandaganda nakuma-excavators

Ama-grates

Chutes

Ama-Hoppers

Amagama Omkhiqizo Nezimpawu Zokuhweba

| Gqoka i-Plate 400, i-Wear Plate 450, i-Wear Plate 500, | I-RAEX 400, | I-RAEX 450, |

| I-RAEX 500, | FORA 400, | FORA 450, |

| FORA 500, | I-QUARD 400, | I-QUARD 400, |

| I-QUARD 450 | I-DILLIDUR 400 V, DILLIDUR 450 V, DILLIDUR 500 V, | I-JFE EH 360LE |

| I-JFE EH 400LE | I-AR400, | I-AR450, |

| I-AR500, | I-SUMI-HARD 400 | I-SUMI-HARD 500 |

Kusukela ngo-2008, i-Jindalai ibilokhu igcina ucwaningo kanye nokuqongelela iminyaka yesipiliyoni sokukhiqiza ukuze kuthuthukiswe amamaki ekhwalithi ahlukene ensimbi ukuze ihlangabezane nesidingo semakethe, njengensimbi evamile ekwazi ukumelana nemihuzuko, insimbi ekwazi ukumelana nemihuzuko kanye nokuqina komthelela ophezulu wepuleti lensimbi elingagugi . Njengamanje, ukushuba kwepuleti lensimbi elimelana nokuhuzuka kuphakathi kuka-5-800mm, ubulukhuni obufika ku-500HBW. Ishidi lensimbi elincanyana kanye nepuleti lensimbi elibanzi kakhulu lenzelwe ukusetshenziswa okukhethekile.