Uhlolojikelele lwe-Grouting Steel Pipe ye-Bridge Pile Foundation

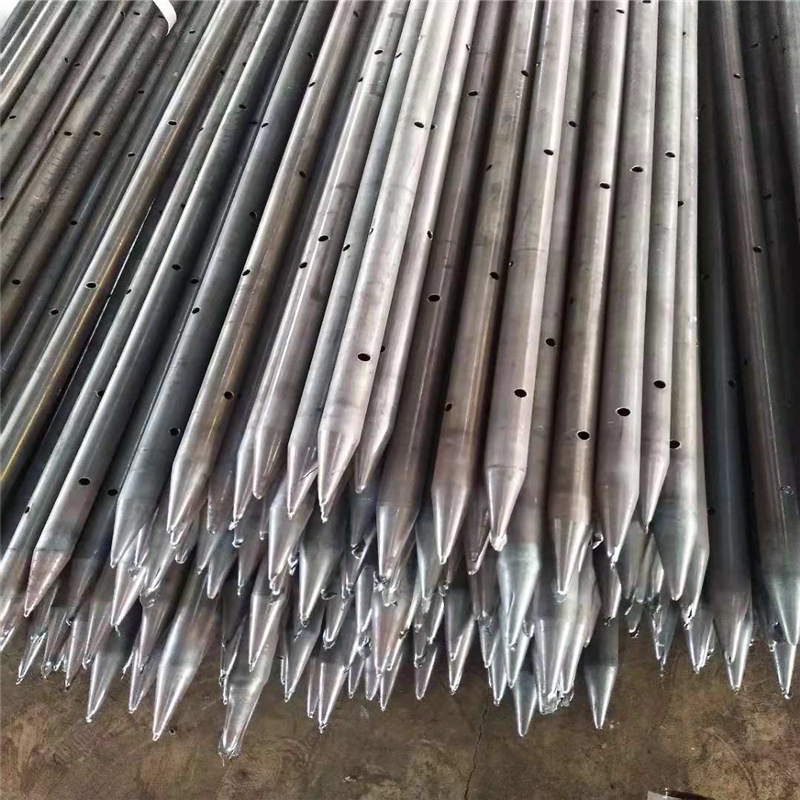

Ipayipi lensimbi ye-Grouting iyisisetshenziswa esisetshenziswa kakhulu sokugaya emikhakheni efana nezakhiwo, imigudu, nobunjiniyela obungaphansi komhlaba. Umsebenzi wayo oyinhloko ukujova izinto zokugaya emigodini engaphansi komhlaba, ukugcwalisa izikhala, nokuthuthukisa umthamo wokuthwala nokuzinza kwesisekelo. Amapayipi e-grouting anezinzuzo zesakhiwo esilula, ukwakhiwa okulula, nemiphumela ebalulekile, ngakho-ke asetshenziswe kabanzi kubunjiniyela obungaphansi komhlaba.

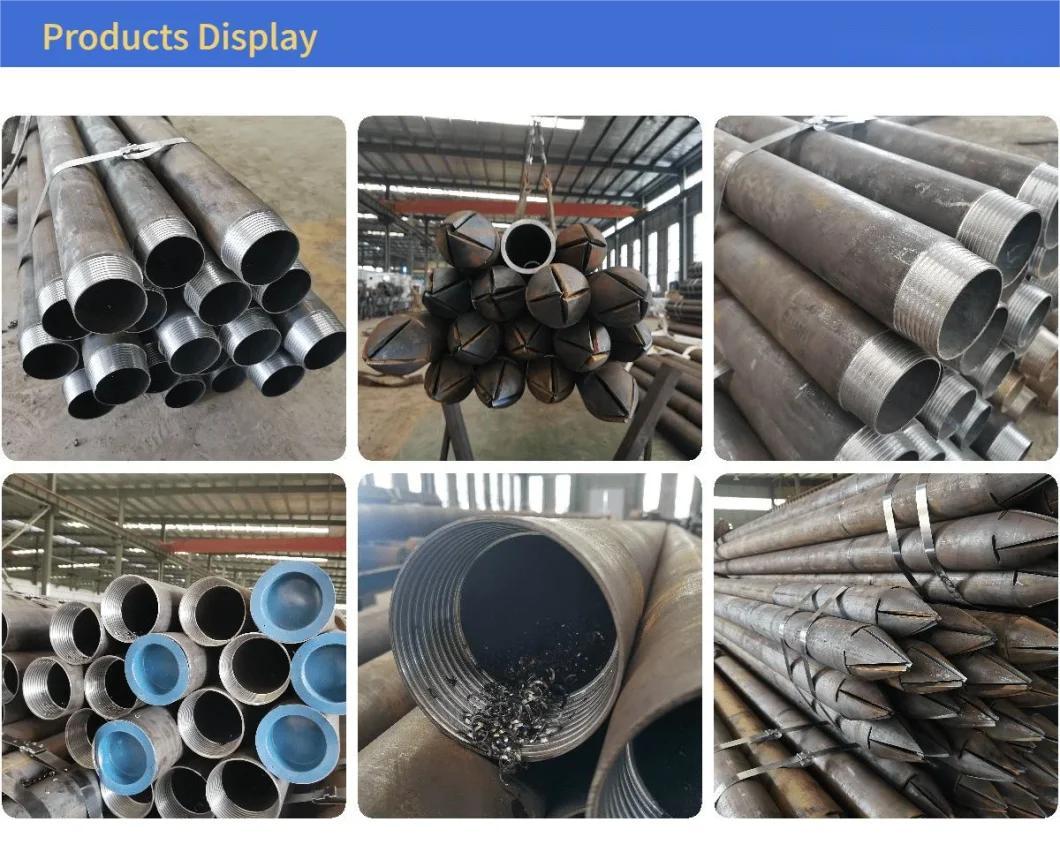

Ukucaciswa kwe-Grouting Steel Pipe ye-Bridge Pile Foundation

| Igama Lomkhiqizo | Ipayipi Lepayipi Lensimbi/Izigxobo Zepayipi Lensimbi/Ipayipi Lensimbi Lokugxusha/I-Geology Drilling Pipe/I-Sub-grade Pile/Micro Pile Tube |

| Amazinga | I-GB/T 9808-2008, API 5CT, ISO |

| Amabanga | DZ40, DZ60, DZ80, R780, J55, K55, N80, L80, P110, 37Mn5, 36Mn2V, 13Cr, 30CrMo, A106 B, A53 B, ST52-4 |

| Ububanzi bangaphandle | 60mm-178mm |

| Ubukhulu | 4.5-20mm |

| Ubude | 1-12M |

| Ukugoba kuvunyelwe | Ingabi ngaphezu kuka-1.5mm/m |

| Indlela Yokucubungula | I-Beveling/Screening/Imbobo Yembobo/Intambo Yendoda/Intambo Yowesifazane/Intambo yeTrapezoidal/Ukukhomba |

| Ukupakisha | Ukuthungatha owesilisa nowesifazane kuzovikelwa izingubo zepulasitiki noma amakepisi epulasitiki Iziphetho zamapayipi ezikhomba zizoba ngenalutho noma ngokwesicelo seklayenti. |

| Isicelo | Ukwakhiwa Komgwaqo Omkhulu/Ukwakhiwa KweMetro/Ukwakhiwa Kwebhuloho/Iphrojekthi Yokuqinisa Umzimba Wentaba /Iphothali Yomhubhe/Isisekelo Esijulile/I-Underpinning njll. |

| Isikhathi sokuthumela | Ngemikhumbi eyinqwaba ngenani elingaphezu kwamathani ayi-100, I-oda elingaphansi kwamathani ayi-100, lizolayishwa ezitsheni, Ukuze uthole i-oda elingaphansi kwamathani angu-5, ngokuvamile sikhetha isitsha se-LCL (Ngaphansi komthwalo wesitsha), ukuze silondoloze izindleko zeklayenti. |

| Imbobo yokuthumela | Ichweba laseQingdao, noma ichweba laseTianjin |

| Isikhathi sohwebo | CIF, CFR, FOB, EXW |

| Isikhathi sokukhokha | 30%TT + 70% TT ngokumelene nekhophi ye-B/L, noma 30%TT + 70% LC. |

Ipayipi Lensimbi Elisetshenziswa Ngokujwayelekile elinamaBanga

| Ibanga | C. | Si | UMn. | P, S | Cu | Ni | Mo | Cr |

| 10 | 0.07-0.14 | 0.17-0.37 | 0.35-0.65 | Ubukhulu.0.035 | Ubukhulu.0.25 | Ubukhulu.0.25 | / | Ubuningi.0.15 |

| 20 | 0.17-0.24 | 0.17-0.37 | 0.35-0.65 | Ubukhulu.0.035 | Ubukhulu.0.025 | Ubukhulu.0.25 | / | Ubukhulu.0.25 |

| 35 | 0.32-0.40 | 0.17-0.37 | 0.50-0.80 | Ubukhulu.0.035 | Ubukhulu.0.25 | Ubukhulu.0.25 | Ubukhulu.0.25 | |

| 45 | 0.42-0,50 | 0.17-0.37 | 0.50-0.80 | Ubukhulu.0.035 | Ubukhulu.0.25 | Ubukhulu.0.25 | Ubukhulu.0.25 | |

| 16Mn | 0.12-0.20 | 0.20-0,55 | 1.20-1.60 | Ubukhulu.0.035 | Ubukhulu.0.25 | Ubukhulu.0.25 | Ubukhulu.0.25 | |

| 12Crmo | 0.08-0.15 | 0.17-0.37 | 0.40-0,70 | Ubukhulu.0.035 | Ubukhulu.0.25 | Ubukhulu.0.30 | 0.40-0,55 | 0.40-0,70 |

| 15Crmo | 0.12-0.18 | 0.17-0.37 | 0.40-0,70 | Ubukhulu.0.035 | Ubukhulu.0.25 | Ubukhulu.0.30 | 0.40-0,55 | 0.80-1.10 |

| 12Cr1Mov | 0.08-0.15 | 0.17-0.37 | 0.40-0,70 | Ubukhulu.0.035 | Ubukhulu.0.25 | Ubukhulu.0.30 | 0.25-0.35 | 0.90-1.20 |

Izakhiwo Zemishini

| Ibanga | Amandla okuqina (Mpa) | Amandla esivuno(Mpa) | Ukwelula(%) |

| 10 | ≥335 | ≥205 | ≥24 |

| 20 | ≥390 | ≥245 | ≥20 |

| 35 | ≥510 | ≥305 | ≥17 |

| 45 | ≥590 | ≥335 | ≥14 |

| 16Mn | ≥490 | ≥325 | ≥21 |

| 12CrMo | ≥410 | ≥265 | ≥24 |

| 15CrMo | ≥440 | ≥295 | ≥22 |

| 12Cr1MoV | ≥490 | ≥245 | ≥22 |

Ukusetshenziswa kwamapayipi ensimbi e-grouting

Ipayipi le-steel grouting liyinto esetshenziswa kakhulu yamapayipi, esetshenziswa kabanzi ezimbonini, ukongiwa kwamanzi, ukwakhiwa, ukuvikela umlilo, neminye imikhakha. Inokumelana nokugqwala okuhle nokumelana nokugqoka, futhi inamandla athile okucindezela.

Amapayipi ensimbi e-grouting ngokuvamile enziwa ngensimbi engagqwali futhi ngenxa yalokho anokumelana nokugqwala okuhle. Ngaphezu kwalokho, ipayipi ye-steel grouting nayo inamandla athile okucindezela futhi ingamelana nenani elithile lokucindezela. Ngaphezu kwalokho, ipayipi ye-steel grouting nayo inokumelana nokugqoka futhi ingasetshenziswa isikhathi eside.

-

I-A106 Crosshole Sonic Logging Welded Tube

-

Ibha Yensimbi Eyindilinga/Induku Yensimbi

-

Ipayipi elingenamthungo le-ASTM A106 Grade B

-

I-A106 GrB Seamless Grouting Steel Pipes for Pile

-

I-A53 Grouting Steel Pipe

-

I-Hollow Grouting Spiral Anchor Rod Steel R32

-

Ihange Lomjovo Lokujova Elingenalutho lika-R25...

-

I-ASTM A312 Ipayipi Lensimbi Engenamthungo