Ithusi

Ukusetshenziswa kwethusi nethusi kwaqala emakhulwini eminyaka adlule, futhi namuhla isetshenziswa kobunye ubuchwepheshe bamuva kanye nezinhlelo zokusebenza ngenkathi isasetshenziswa kuyizinhlelo zokusebenza zendabuko ezifana nezinsimbi zomculo, ama-eyelets ethusi, izindatshana zokuhlobisa kanye nehardware kampompi nomnyango.

I-Brass Yenziwe Ngani?

I-Brass iyingxubevange eyenziwe ngethusi ne-zinc ukuze kukhiqizwe izinto ezinohlu olubanzi lokusetshenziswa kobunjiniyela. Ukwakheka kwethusi kunikeza insimbi indawo yokuncibilika elungele izinhlelo zokusebenza eziningi, okuhlanganisa nokufanelekela ukujoyina kusetshenziswa indlela yokubraza. Iphuzu lokuncibilika lethusi liphansi kunekhopha cishe ku-920 ~ 970 degrees Celsius kuye ngenani lokwengezwa kwe-Zn. Iphuzu lokuncibilika kwethusi liphansi kunelethusi ngenxa ye-Zn eyengeziwe. Ama-alloys ethusi angahluka ekubunjweni kwe-Zn kusukela kokuncane okufika ku-5% (okuvame ukubizwa ngokuthi izinsimbi ze-Gilding) kuya ngaphezu kuka-40% njengoba kusetshenziswa kuma-machining brasses. Igama elingajwayelekile elisetshenziswa ithusi lethusi, lapho kusetshenziswa khona izithasiselo ezithile zamathini.

Ithusi lisetshenziselwa ini?

Ukwakheka kwethusi kanye nokwengezwa kwe-zinc ethusi kuphakamisa amandla futhi kunikeza uhla lwezici, okwenza amathusi abe uhla lwezinto ezihlukahlukene kakhulu. Zisetshenziselwa amandla azo, ukumelana nokugqwala, ukubukeka nombala, kanye nokusebenza kalula nokujoyina. I-alpha brasses yesigaba esisodwa, equkethe cishe u-37% Zn, i-ductile kakhulu futhi kulula ukusebenza ngokubandayo, i-weld kanye ne-braze. Izigaba ezimbili ze-alpha-beta brasses ngokuvamile ziyashisa.

Ingabe kukhona ukwakheka kwethusi okungaphezu kokukodwa?

Kunamathusi amaningi anezinhlobo ezahlukene nezici ezenzelwe izinhlelo zokusebenza ezithile ngezinga lokwengezwa kwe-zinc. Amazinga aphansi okwengezwa kwe-Zn avame ukubizwa nge-Guilding Metal noma i-Red Brass. Ngenkathi amazinga aphezulu e-Zn angama-alloys afana ne-Cartridge Brass, i-Free Machining Brass, i-Naval Brass. Lezi zethusi zakamuva nazo zinokungezwa kwezinye izakhi. Ukwengezwa komthofu wethusi sekusetshenziswe iminyaka eminingi ukusiza ubuciko bezinto ngokuheha amaphuzu okuphuka kwe-chip. Njengoba ubungozi kanye nobungozi bomthofu kuye kwaqashelwa ukuthi muva nje kushintshwe izakhi ezifana ne-silicon ne-bismuth ukuze kuzuzwe isici somshini esifanayo. Lokhu manje sekwaziwa njengokuhola okuphansi noma izithusi zamahhala eziholayo.

Ingabe ezinye izakhi zingengezwa?

Yebo, amanani amancane wezinye izakhi ze-alloying angase afakwe ethusi nasethusini. Izibonelo ze-Commons ziwumthofu wekhono lomshini njengoba kushiwo ngenhla, kodwa futhi i-arsenic yokumelana nokugqwala ukuze i-dezincification, ithini lamandla nokugqwala.

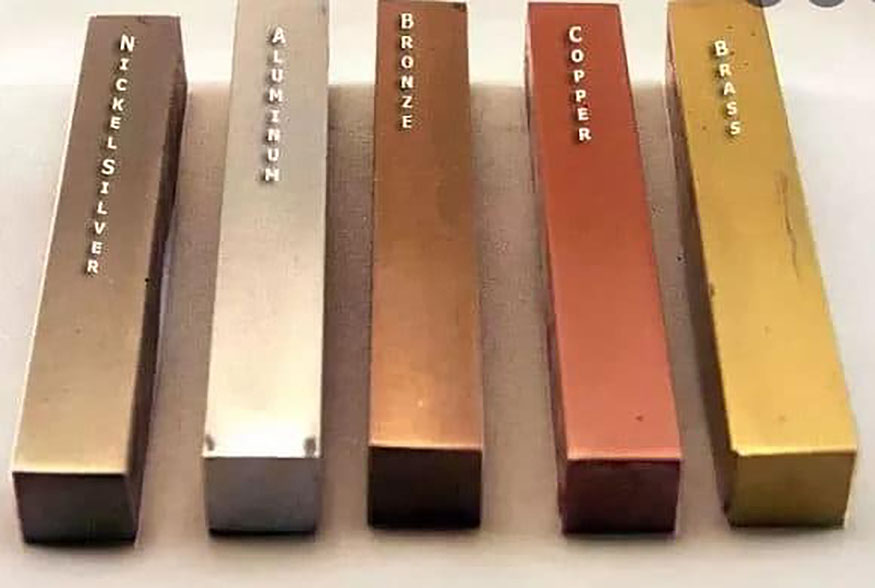

Umbala Wethusi

Njengoba okuqukethwe kwe-zinc kwanda, umbala uyashintsha. Ama-alloys e-Zn aphansi ngokuvamile angafana nethusi ngombala, kuyilapho ama-alloys e-zinc aphezulu abonakala esagolide noma aphuzi.

Ukwakheka Kwamakhemikhali

AS2738.2 -1984 Okunye ukucaciswa okucishe kulingane

| Inombolo ye-UNS | NJENGOBA No | Igama Elivamile | Inombolo ye-BSI | Inombolo ye-ISO | I-JIS No | Ithusi % | Zinc % | Ukuhola % | Abanye % |

| C21000 | 210 | 95/5 Gilding Metal | - | kuZn5 | C2100 | 94.0-96.0 | ~ 5 | <0.03 | |

| C22000 | 220 | 90/10 Gilding Metal | CZ101 | KuZn10 | C2200 | 89.0-91.0 | ~ 10 | <0.05 | |

| C23000 | 230 | 85/15 Gilding Metal | CZ102 | CuZn15 | C2300 | 84.0-86.0 | ~ 15 | <0.05 | |

| C24000 | 240 | 80/20 Gilding Metal | CZ103 | kuZn20 | C2400 | 78.5-81.5 | ~ 20 | <0.05 | |

| C26130 | 259 | 70/30 Arsenical Brass | CZ126 | I-CuZn30As | ~C4430 | 69.0-71.0 | ~ 30 | < 0.07 | I-Arsenic 0.02-0.06 |

| C26000 | 260 | 70/30 Ithusi | CZ106 | KuZn30 | C2600 | 68.5-71.5 | ~ 30 | <0.05 | |

| C26800 | 268 | Ithusi Eliphuzi (65/35) | CZ107 | CuZn33 | C2680 | 64.0-68.5 | ~ 33 | < 0.15 | |

| C27000 | 270 | 65/35 Wire Brass | CZ107 | CuZn35 | - | 63.0-68.5 | ~ 35 | < 0.10 | |

| C27200 | 272 | 63/37 Ithusi Elivamile | CZ108 | CuZn37 | C2720 | 62.0-65.0 | ~ 37 | < 0.07 | |

| C35600 | 356 | I-Engraving Brass, 2% Ukuhola | - | I-CuZn39Pb2 | C3560 | 59.0-64.5 | ~ 39 | 2.0-3.0 | |

| C37000 | 370 | Ithusi Lokuqopha, Ukuhola okungu-1%. | - | I-CuZn39Pb1 | ~C3710 | 59.0-62.0 | ~ 39 | 0.9-1.4 | |

| C38000 | 380 | Ingxenye yethusi | CZ121 | I-CuZn43Pb3 | - | 55.0-60.0 | ~ 43 | 1.5-3.0 | I-Aluminium 0.10-0.6 |

| C38500 | 385 | I-Free Cutting Brass | CZ121 | CuZn39Pb3 | - | 56.0-60.0 | ~ 39 | 2.5-4.5 |

Ama-Brasses avame ukusetshenziselwa ukubukeka kwawo

| Inombolo ye-UNS | Igama Elivamile | Umbala |

| C11000 | I-ETP Copper | Uphinki Othambile |

| C21000 | 95/5 Gilding Metal | Red Brown |

| C22000 | 90/10 Gilding Metal | Igolide Lethusi |

| C23000 | 85/15 Gilding Metal | Igolide Elimnyama |

| C26000 | 70/30 Ithusi | Igolide Eliluhlaza |

I-Gilding Metal

I-C22000, 90/10 Gilding metal, ihlanganisa umbala osagolide ocebile kanye nenhlanganisela engcono kakhulu yamandla, i-ductility kanye nokumelana nokugqwala kwama-alloys angenalutho e-Cu-Zn. Ishintsha isimo sezulu ibe nemibala yethusi ecebile. Inekhono elihle kakhulu lokudweba elijulile, kanye nokumelana nokugqwala kwemigodi esimweni sezulu esibi namanzi. Isetshenziswa ku-architectural fascias, ubucwebe, i-ornamental trim, izibambo zeminyango, ama-escutcheons, i-hardware yasolwandle.

Amathusi aphuzi

I-C26000, 70/30 Brass ne-C26130, i-Arsenical brass, ine-ductility namandla amahle kakhulu, futhi yizithusi ezisetshenziswa kakhulu. Ithusi le-arsenical liqukethe ukungezwa okuncane kwe-arsenic, okuthuthukisa kakhulu ukumelana nokugqwala emanzini, kodwa kufana ngokuphumelelayo. Lawa ma-alloys anombala ophuzi ogqamile ohlukile ovame ukuhlotshaniswa nethusi. Zinenhlanganisela enkulu yamandla kanye ne-ductility kuma-alloys e-Cu-Zn, kuhlanganiswe nokungagqwala okuhle. I-C26000 isetshenziselwa ukwakha, iziqukathi ezidwetshiwe neziphothiweyo, amatheminali kagesi nezixhumi, izibambo zezicabha, kanye nehardware ye-plumbers. I-C26130 isetshenziselwa ishubhu nokufakwa kuthintana namanzi, okuhlanganisa namanzi aphuzwayo.

I-C26800, Ithusi Eliphuzi, isigaba esisodwa se-alpha brass esinokuqukethwe okuphansi kwethusi. Isetshenziswa lapho izakhiwo zayo ezijulile zokudweba kanye nezindleko eziphansi zinikeza inzuzo. Lapho izinhlayiya ezishiselwe zesigaba se-beta zingase zakheke, kunciphise i-ductility kanye nokumelana nokugqwala.

Izinsimbi nezinye izakhi

I-C35600 ne-C37000, i-Engraving brass, zingamabhusi e-alpha-beta angama-60/40 anamazinga ahlukene omthofu angeziwe ukuze anikeze izici zamahhala zokwenza imishini. Zisetshenziswa kabanzi kumapuleti aqoshiwe nama-plaque, i-hardware yabakhi, amagiya. Akumele zisetshenziselwe umsebenzi ofakwe i-asidi, okumele kusetshenziswe ithusi lesigaba esisodwa se-alpha.

I-C38000, i-Section brass, iyithusi eliholayo le-alpha/beta eliphuma kalula elinesengezo esincane se-aluminium, esinikeza umbala osagolide ogqamile. Umthofu unikeza izici zokusika mahhala. I-C38000 itholakala njengezinduku, amashaneli, amaflethi nama-engeli, ngokuvamile asetshenziswa kuma-hardware abakhi.

I-C38500, ithusi lokusika, iyindlela ethuthukisiwe kakhulu ye-60/40 yethusi, enezici ezinhle kakhulu zokusika mahhala. Isetshenziswa ekukhiqizeni ngobuningi bezingxenye zethusi lapho okuphumayo okuphezulu nokuphila kwamathuluzi okude kakhulu kuyadingeka, futhi lapho kungadingeki khona ukwakheka okubandayo ngemva komshini.

Uhlu Lwemikhiqizo Yethusi

● Ifomu Lomkhiqizo

● Imikhiqizo eyisicaba egoqiwe

● Izinti, imigoqo kanye nezigaba

● Ukuqambela isitoko nokuqamba

● Amashubhu angenamthungo wezishintshi zokushisa

● Amashubhu angenamthungo okufaka umoya nesiqandisi

● Amashubhu angenamthungo ngezinjongo zobunjiniyela

● Intambo ngezinjongo zobunjiniyela

● Intambo yezinjongo zikagesi

I-Jindalai Steel Group inikezela ngemikhiqizo yethusi ehlukahlukene ngobukhulu nenani ukuze ihlangabezane nezidingo zanoma iyiphi iphrojekthi. Futhi samukela amaphethini angokwezifiso, osayizi, umumo, nemibala. Thumela uphenyo lwakho futhi sizokujabulela ukubonisana nawe ngobuchwepheshe.

I-HOTLINE:+86 18864971774WECHAT: +86 18864971774WHATSAPP:https://wa.me/8618864971774

I-IMEYILI:jindalaisteel@gmail.com sales@jindalaisteelgroup.com Iwebhusayithi:www.jindalaisteel.com

Isikhathi sokuthumela: Dec-19-2022