1. Isinyathelo sokuqala: Ukuncibilika

I-Aluminium yenziwa kusetshenziswa i-electrolysis esikalini sezimboni futhi izincibilikisi ze-aluminium zidinga amandla amaningi ukuze zisebenze kahle. Izincibilikisi zivame ukutholakala eduze kwezitshalo ezinkulu zikagesi ngenxa yesidingo sazo samandla. Noma yikuphi ukunyuka kwezindleko zamandla, noma inani lamandla adingekayo ukuze kucwengwe i-aluminiyamu ibe yizinga eliphezulu, kwandisa izindleko zamakhoyili e-aluminium. Ngaphezu kwalokho, i-aluminium ehlakaziwe iyahlukanisa futhi iye endaweni yokuqoqa. Le ndlela futhi inezidingo ezinkulu zamandla, ezithinta amanani emakethe ye-aluminium.

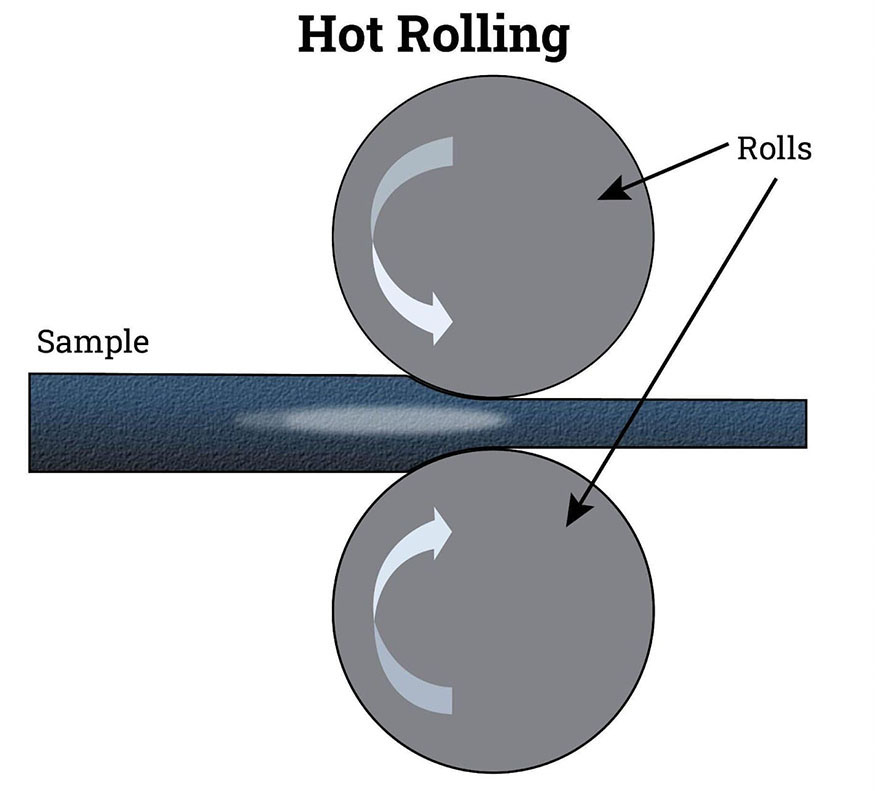

2. Isinyathelo Sesibili: I-Hot Rolling

Ukugoqa okushisayo kungenye yezindlela ezivame ukusetshenziswa kakhulu zokunciphisa i-aluminium slab. Lapho kuginqika okushisayo, insimbi ishiswa ngaphezu kwephuzu lokuphinda ikristale ukuze ikhubazeke futhi iqhubeke iyilolonge. Khona-ke, lesi sitokwe sensimbi sidluliswa ngepheya elilodwa noma amaningi emiqulu. Lokhu kwenzelwa ukunciphisa ukujiya, ukwenza ukujiya okufanayo, nokufeza ikhwalithi yomshini oyifunayo. Ikhoyili ye-aluminium yenziwa ngokucubungula ishidi ku-1700 degrees Fahrenheit.

Le ndlela ingakhiqiza ubujamo obunamapharamitha afanele wejiyomethri kanye nezici ezibonakalayo ngenkathi igcina ivolumu yensimbi ingashintshi. Le misebenzi ibalulekile ekukhiqizeni izinto eseziqediwe neziqediwe, njengamapuleti namashidi. Kodwa-ke, imikhiqizo egoqiwe eqediwe ihluke kumakhoyili abandayo, azochazwa ngezansi, ngoba anogqinsi oluncane olufanayo ngenxa yemfucumfucu emincane engaphezulu.

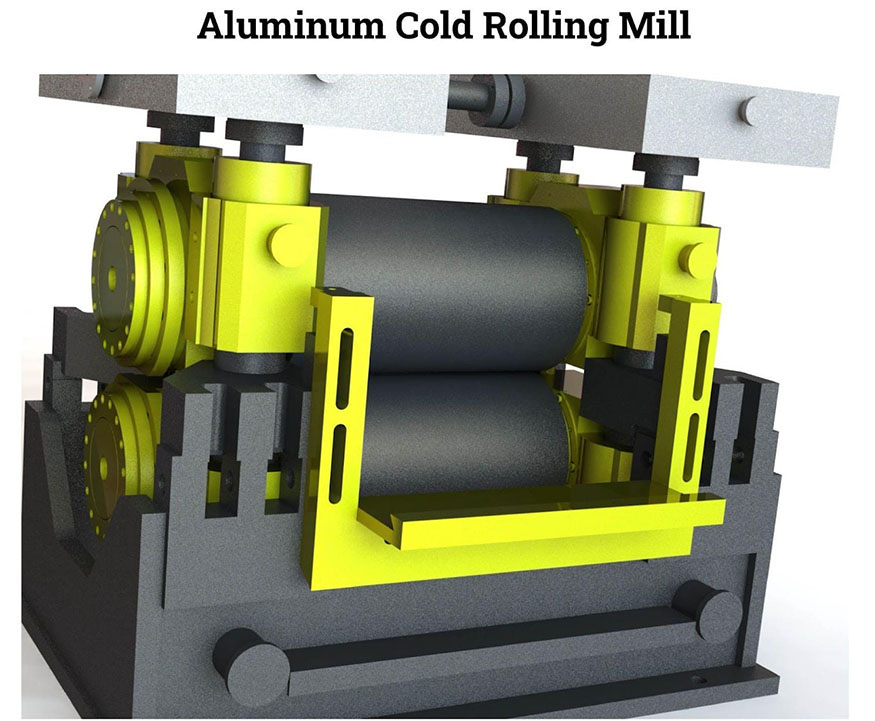

3. Isinyathelo Sesithathu: I-Cold Rolling

Ukugoqa okubandayo kwamapheshana ensimbi kuyindawo eyingqayizivele yomkhakha wokusebenza kwensimbi. Inqubo "yokugoqa okubandayo" ihlanganisa ukubeka i-aluminium ngokusebenzisa ama-roller ezingeni lokushisa eliphansi kunamazinga okushisa ayo okuvuselela kabusha. Ukukhama nokucindezela insimbi kukhulisa amandla ayo okukhiqiza nobulukhuni. Ukugoqeka okubandayo kwenzeka ezingeni lokushisa eliqinisa umsebenzi (izinga lokushisa elingaphansi kwezinga lokushisa lekristalu lento), futhi ukuginqika okushisayo kwenzeka ngaphezu kwezinga lokushisa eliqinisa umsebenzi- lona umehluko phakathi kokuginqika okushisayo nokuginqika okubandayo.

Izimboni eziningi zisebenzisa inqubo yokwelashwa kwensimbi eyaziwa ngokuthi ukugoqa okubandayo ukuze kukhiqizwe i-strip neshidi lensimbi enegeji yokugcina oyifunayo. Amaroli avame ukushiselwa ukuze asize i-aluminium isebenze kakhudlwana, futhi okokugcoba kusetshenziselwa ukuvimbela umucu we-aluminium ukuthi unganamatheli kumaroli. Ukuze kulungiswe kahle ukusebenza, ukunyakaza kwamaroli nokushisa kungashintshwa. Umucu we-aluminium, osuvele uginqike ngokushisa, kanye nezinye izinqubo, okuhlanganisa ukuhlanzwa nokwelashwa, upholiswa ulingane nezinga lokushisa elilingana negumbi ngaphambi kokuba ufakwe emshinini wokugaya obandayo embonini ye-aluminium. I-Aluminium ihlanzwa ngokuyiwasha ngesihlanzi futhi lokhu kwelashwa kwenza ikhoyili ye-aluminiyamu iqine ngokwanele ukuba imelane nokugingqika okubandayo.

Ngemva kokuba lezi zinyathelo zokulungiselela sezilungisiwe, amapheshana adlula ngokuphindaphindiwe kuma-roller, kancane kancane alahlekelwa ukushuba. Izindiza ze-lattice zensimbi ziyaphazamiseka futhi azimiswe kuyo yonke inqubo, okuholela kumkhiqizo wokugcina oqinile, oqinile. Ukugoqa okubandayo kungenye yezindlela ezidume kakhulu zokuqinisa i-aluminiyamu ngoba kunciphisa ukujiya kwe-aluminium njengoba igaywa futhi iphushwa ngamarola. Indlela yokugoqa ebandayo ingehlisa ukujiya kwekhoyili ye-aluminium kufika ku-0.15 mm.

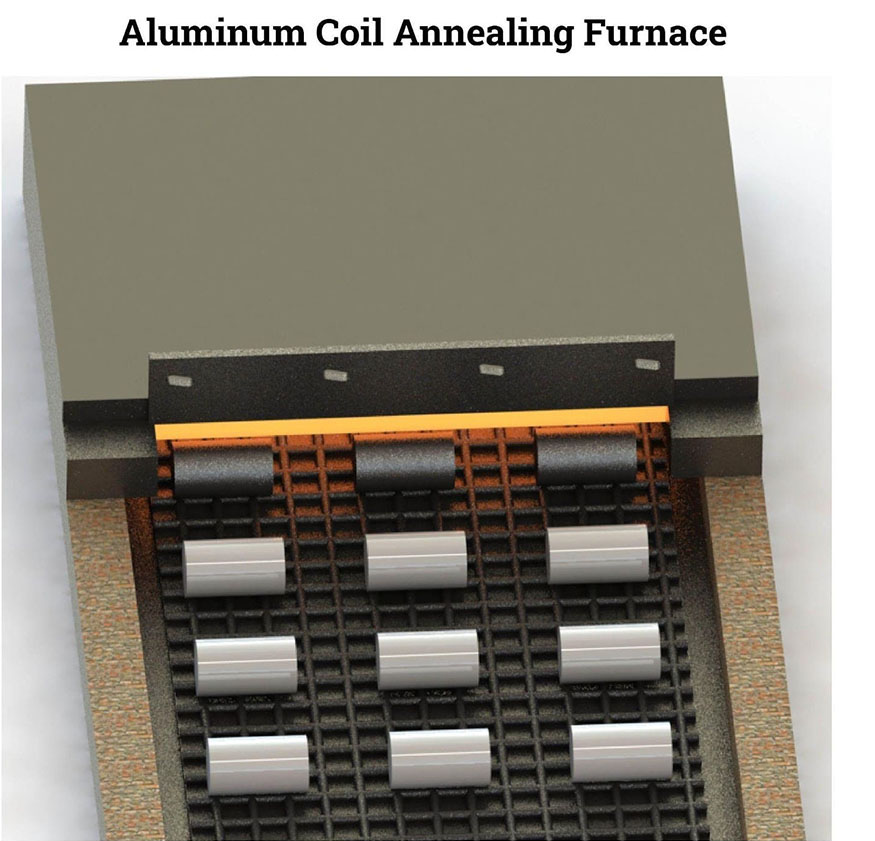

4. Isinyathelo Sesine: Ukuhlanganisa

Inqubo yokuhoxisa iwukwelapha ukushisa okusetshenziselwa kakhulukazi ukwenza into ethambile kakhulu futhi ingaqini. Ukuncipha kokugudluka esakhiweni sekristalu sezinto ezibanjwayo kubangela lokhu kushintshwa kobulukhuni nokuvumelana nezimo. Ukuze ugweme ukwehluleka okufiphalayo noma ukwenza okokusebenza kusebenze kangcono emisebenzini elandelayo, ukudonsa kuvamise ukwenziwa ngemva kokuthi okubalulekile kwenziwe inqubo yokusebenza eqinile noma ebandayo.

Ngokusetha kabusha ngempumelelo ukwakheka okusanhlamvu okucwebezelayo, ukuhlanganisa kubuyisela izindiza ezishelelayo futhi kuvumela ukulolongwa okwengeziwe kwengxenye ngaphandle kwamandla amakhulu. Ingxubevange ye-aluminiyamu eqiniswe emsebenzini kufanele ishisiswe kumazinga okushisa athile aphakathi kuka-570°F no-770°F isikhathi esinqunyiwe, esisukela cishe emaminithini angamashumi amathathu kuya emahoreni amathathu. Ubukhulu bengxenye ekhishwayo kanye nengxubevange eyenziwe ngayo inquma izinga lokushisa nesikhathi, ngokulandelana.

I-Annealing iphinde iqinise ubukhulu bengxenye, iqede izinkinga ezilethwa ukungezwani kwangaphakathi, futhi kunciphisa ukucindezelwa kwangaphakathi okungase kuvele, ngokwengxenye, phakathi nezinqubo ezifana nokubumba okubandayo noma ukulingisa. Ukwengeza, ama-alloys e-aluminium angelapheki angancishiswa ngempumelelo. Ngakho-ke, isetshenziswa kaningi ezingxenyeni ze-aluminium eziphonsiwe, ezikhishiwe, noma ezifojiwe.

Ikhono le-material lokwakheka lithuthukiswa ngokuhushula. Ukucindezela noma ukugoba kanzima, izinto eziphukayo kungaba inselele ngaphandle kokubangela ukuphuka. Izinsiza zokuhlanganisa ekususeni le ngozi. Ukwengeza, i-annealing ingakhuphula ukusebenza komshini. Ukuba brittleness okwedlulele kwento kungase kubangele ukuguga ngokweqile kwamathuluzi. Ngokufaka i-anneal, ubulukhuni bempahla bungancipha, okunganciphisa ukuguga kwamathuluzi. Noma yikuphi ukungezwani okusele kuqedwa ngokunqanyulwa. Ngokuvamile kuhle kakhulu ukunciphisa ukungezwani okuyinsalela lapho kungenzeka khona ngoba kungase kubangele imifantu nezinye izinkinga zemishini.

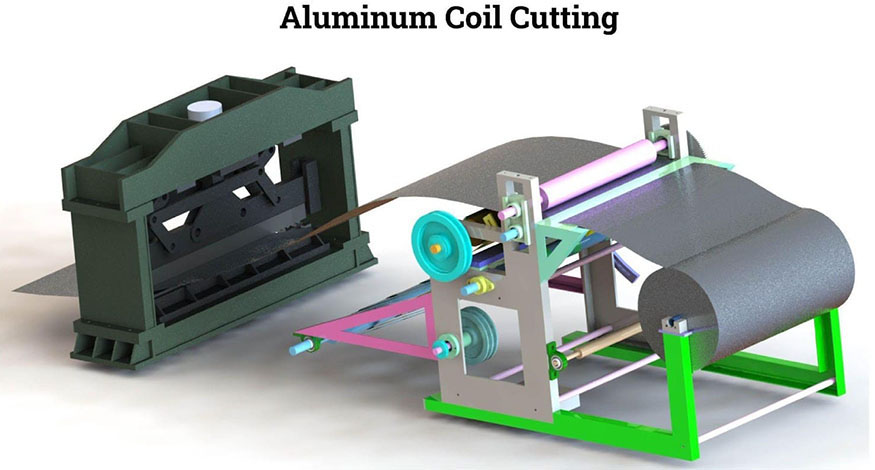

5. Isinyathelo sesihlanu: Ukusika nokusika

Amakhoyili e-aluminiyamu ayengenziwa ngomqulu owodwa omude kakhulu oqhubekayo. Ukupakisha ikhoyili ibe yimiqulu emincane, noma kunjalo, idinga ukusikwa. Ukwenza lo msebenzi, amaroli e-aluminium asetshenziswa emishinini yokusika lapho ama-blade acijile ngendlela emangalisayo enza ukusikeka okunembile. Kudingeka amandla amaningi ukwenza lo msebenzi. Ama-slitter ahlukanisa umqulu ube yizicucu ezincane lapho amandla asetshenzisiwe edlula amandla aqinile e-aluminium.

Ukuqala inqubo yokusika, i-aluminium ifakwa ku-uncoiler. Ngemva kwalokho, idluliswa eqoqweni lemimese ejikelezayo. Ama-blades abekwe ukuze athole unqenqema oluhle kakhulu lokuhlukanisa, kucatshangelwa ububanzi obudingekayo kanye nokuvunyelwa. Ukuze uqondise i-slit material ku-recoiler, izinto ezisetshenziswayo kamuva zondliwa ngezihlukanisi. I-aluminium ibe isihlanganiswa futhi isongwe kukhoyili ukuze ilungiselele ukuthunyelwa.

I-Jindalai Steel Group iyiNkampani Ye-Aluminium Ehamba Phambili futhi Ihlinzeka Ngekhoyili ye-aluminium/sheet/plate/strip/pipe/foil. Sinekhasimende elivela ePhilippines, Thane, Mexico, Turkey, Pakistan, Oman, Israel, Egypt, Arab,Vietnam, Myanmar, India njll. Thumela uphenyo lwakho futhi sizokujabulela ukubonisana nawe ngokomsebenzi.

I-HOTLINE:+86 18864971774WECHAT: +86 18864971774WHATSAPP:https://wa.me/8618864971774

I-IMEYILI:jindalaisteel@gmail.com sales@jindalaisteelgroup.com Iwebhusayithi:www.jindalaisteel.com

Isikhathi sokuthumela: Dec-19-2022