I-Brass iyinsimbi ye-alloy eyenziwe ngethusi ne-zinc. Ngenxa yezakhiwo eziyingqayizivele zethusi, engizongena ngazo ngemininingwane eyengeziwe ngezansi, ingenye yama-alloys asetshenziswa kakhulu. Ngenxa yokuguquguquka kwayo, kunezimboni nemikhiqizo ebonakala ingapheli esebenzisa le alloy.

1. IZIMPAHLA ZETHUSI EZIHLUKENEYO

Izilinganiso ze-zinc nethusi ngaphakathi kwethusi zingahlukahluka, zenze uhla lwethusi olunezici ezihlukahlukene. Ngenxa yokuhlukahluka kwe-alloy, izakhiwo zethusi azikho yonke indawo. Kodwa, lawa ma-alloys aziwa ngokwakheka kalula (okungukuthi ukusebenziseka kalula) kanye nokugcina amandla aphezulu ngemva kokwakhiwa. Wonke ama-brasses aziwa njenge-ductile—izinguquko ezinokuqukethwe kwe-zinc ephansi zidonsa kakhulu futhi ukuhluka okunokuqukethwe okuphezulu kwe-zinc kuncane kakhulu.

Ngokufanayo nethusi, ithusi liyindawo yokuzalela empofu yamagciwane. Le khwalithi iyenza ibe yimpahla efanelekile yezinto zokugezela zokugezela kanye nezibambo zeminyango, kanye nezicelo zezokwelapha.

1. UKUSETSHENZISWA OKUJWAYELEKILE KWETHUSI

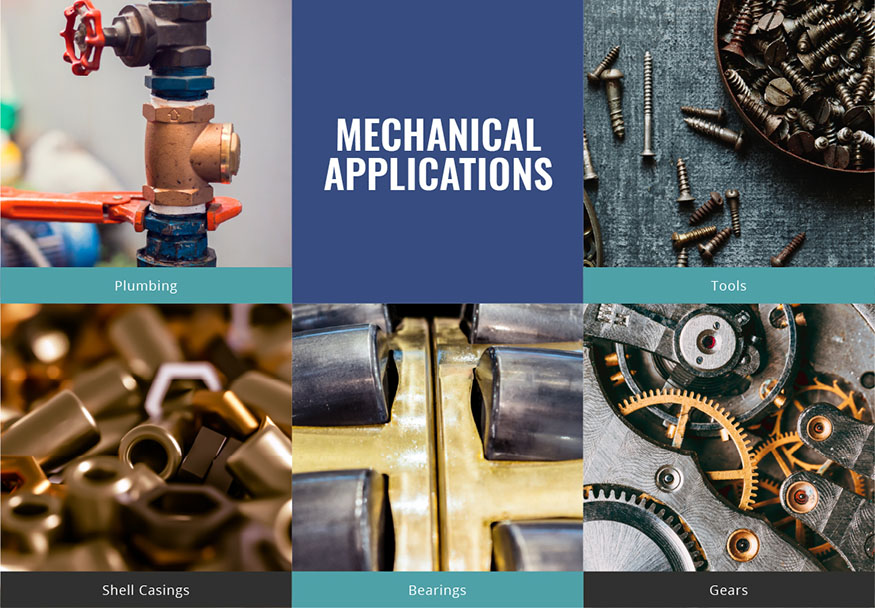

I-Brass isetshenziswa kakhulu ezinhlelweni ezihlobisa neziwumshini. Ngenxa yezakhiwo zayo eziyingqayizivele, ezihlanganisa ukumelana nokugqwala, ukusetshenziswa okuvamile kwethusi kufaka phakathi izinhlelo zokusebenza ezidinga ukungqubuzana okuphansi. Lezi zinhlelo zokusebenza zingabandakanya okokufaka (izixhumi nezixhumi), amathuluzi, izingxenye zikagesi, nezingxenye zezinhlamvu.

2. IZICELO ZOKUHLOBISA

Ngaphandle kwezakhiwo zayo zokulwa namagciwane, inani lobuhle bethusi lenza kube ukukhetha okudumile kwezinhlelo zokusebenza zokuhlobisa. Umbala wayo ungahluka ukusuka kwegolide elikhanyayo nesiliva yonke indlela kuye kobomvu.

Ukufakwa komshini wokuwasha izitsha okuhlala kanye nezixhumi zesibani kuvame ukwenziwa ngethusi, njengoba zombili zibukeka zikhanga futhi zimelana namagciwane.

3. IZICELO ZEMITHETHO

Kusukela kumagobolondo esibhamu se-M-16 kuya kumabheringi namagiya okusetshenziswa nsuku zonke, ithusi lisetshenziswa kakhulu ekusebenzeni kwemishini. Amathuluzi enziwe ngethusi ayaziwa ukuthi anesikhathi eside futhi anesidingo esincishisiwe sokulola.

4. IZINGUBO ZOMCULO

Uma uke wabamba iqhaza ebhendini yekhonsathi, ibhendi emashayo, noma mhlawumbe i-symphony, cishe uyazi kakhulu ithusi elikuzungezile. Amacilongo, izimpondo zesiFulentshi, ama-trombones, ama-baritones, nama-tuba angezinye zezinsimbi zethusi ezidume kakhulu.

5. ITHUSI LIKAJINDALAI

I-Jindalai Steel Group inikezela ngemikhiqizo yethusi ehlukahlukene ngobukhulu nenani ukuze ihlangabezane nezidingo zanoma iyiphi iphrojekthi. Sigcina ithusi le-ASTM, elinikeza i-ductility ephezulu kakhulu yanoma yimuphi umkhiqizo wethusi ophuzi. Imelana kakhulu nesimo sezulu futhi ilungele ukusetshenziswa ezindaweni ezigqwalile.

Sifaka amashidi ethusi namakhoyili ngogqinsi ukusuka ku-0.05 ukuya ku-50mm, futhi ku-annealed, ikota eqinile, eqinile uhhafu, kanye nolaka oluqinile. Amanye ama-temers nama-alloys ayatholakala futhi.

I-HOTLINE:+86 18864971774WECHAT: +86 18864971774WHATSAPP:https://wa.me/8618864971774

I-IMEYILI:jindalaisteel@gmail.com sales@jindalaisteelgroup.com Iwebhusayithi:www.jindalaisteel.com

Isikhathi sokuthumela: Dec-19-2022